A chrome–molybdenum structural steel grade engineered for welded pressure equipment and elevated‑temperature service. Supplied to European EN standards, 13CrMo4‑5 (often specified for boilers, pressure vessels and high‑temperature piping) combines improved creep resistance at raised temperatures with good weldability and resistance in corrosive (including sour) environments.

Key specifications

- Standards: EN 10028‑2:2009 (plates for pressure purposes) and EN 10216‑2:2014 (seamless tubes for pressure purposes).

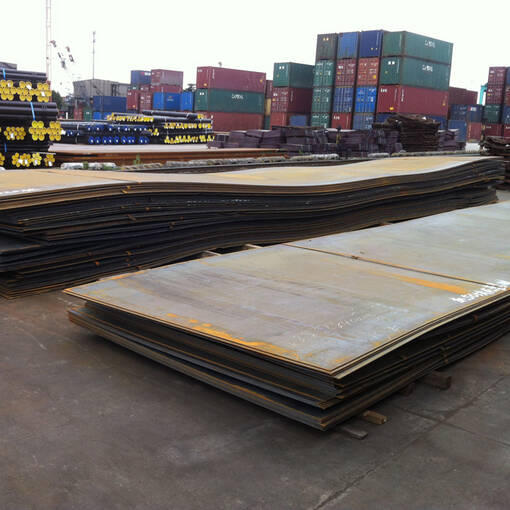

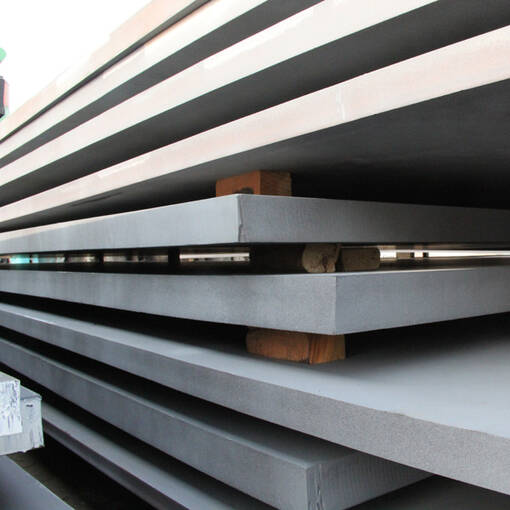

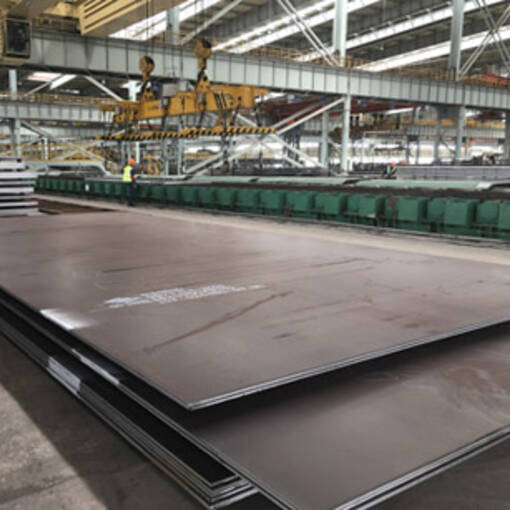

- Product forms: flat plates/plates and seamless pipes/tubes manufactured to the EN delivery conditions.

- Main alloying elements: chromium (Cr) and molybdenum (Mo), with carbon (C), silicon (Si), manganese (Mn), phosphorus (P), sulfur (S), nitrogen (N) and copper (Cu) typically controlled in the chemistry.

Performance features

- Designed for elevated‑temperature strength and improved creep resistance compared with plain carbon steels.

- Good weldability when appropriate procedures are followed (preheat/post‑weld heat treatment per project specifications may be required).

- Strong suitability for use in sour service and corrosive process environments common to oil & gas and petrochemical applications.

Typical applications

- Boiler and steam‑generation components

- Welded pressure vessels and heat exchangers

- High‑temperature piping and fittings in petrochemical, oil & gas and power‑generation plants

Ordering and supply notes

- Supplied to EN 10028‑2 for plates and EN 10216‑2 for seamless tubes — specify the applicable standard, required delivery condition, dimensions (thickness/width or diameter/wall thickness), and any required inspection/traceability (e.g., heat number, mill test certificate) when requesting a quote.

- Additional services such as cutting, machining, edge preparation, NDT or heat treatment may be available; confirm scope with the supplier.

If you need specific size ranges, mechanical property values, or heat‑treatment/inspection details, provide the intended application and delivery requirements so suppliers can supply compliant certificates and dimensional options.

Product Details

Harmonized commodity

Country of origin:

China

Industrial sector: