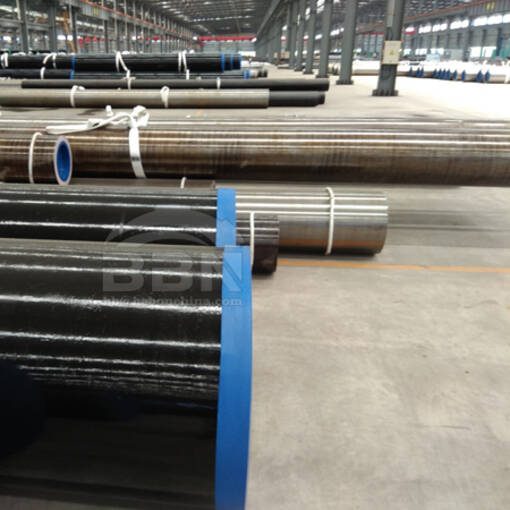

High-strength carbon steel line pipe manufactured to API 5L X60 (ISO 3183 L415) specification for demanding oil & gas, petrochemical and water transmission applications. Grade X60 (also designated L415) indicates a minimum yield strength of 415 MPa, making this pipe suitable for onshore and offshore linepipe projects, replacements and pipeline expansions in high-pressure and high-temperature service.

Key features

- Standards: API 5L X60 / ISO 3183 L415 (API 5L 45th edition, 2013)

- Yield strength: 415 MPa (L415)

- Product forms: available in seamless and welded constructions (including LSAW), suitable for linepipe use

- PSL classification: X60 PSL1 and PSL2 are aligned under the cited API edition

Typical chemical composition (as supplied in specification):

- Carbon (C): 0.26% (nominal/maximum as stated)

- Manganese (Mn): 1.40% (with possible specified allowance)

- Silicon (Si): 0.45%

- Sulfur (S): 0.030% (max)

- Phosphorus (P): 0.030% (max)

- Copper (Cu): 0.50%

- Nickel (Ni): 0.50%

- Chromium (Cr): 0.50%

- Molybdenum (Mo): 0.15%

Applications

- Transmission of crude oil and natural gas (onshore and offshore pipelines)

- Petrochemical feedstock lines

- Water distribution and irrigation lines where high strength is required

- Pipeline replacement and expansion projects

Commercial and logistical notes

- Supplied to API 5L certification requirements; testing and inspection can be performed per purchaser requirements

- Commonly stocked and distributed for rapid delivery to major project hubs (regional distributor presence referenced in global markets)

- Available to order in required lengths, wall thicknesses and end-preparation options per project specifications (please confirm dimensional and testing requirements when enquiring)

For procurement teams: specify required product form (seamless vs welded/LSAW), PSL level, diameter, wall thickness (schedule), end preparation, testing/certification needs and delivery schedule to obtain an accurate quotation and lead time.