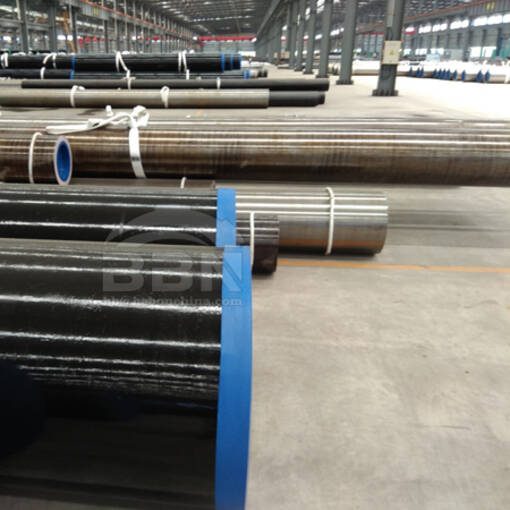

High-strength carbon steel line pipe engineered for oil, gas and water transmission. Manufactured to API 5L specifications as Grade X52, these pipes are supplied in both seamless and welded forms and are offered in PSL1 and the higher-performance PSL2 levels to meet varying project and regulatory requirements.

Key features

- Material: API 5L X52 carbon steel (seamless and welded options)

- Mechanical properties: nominal minimum yield ~52,000 psi and minimum tensile ~66,000 psi (per API X52 grade specification)

- Standards & certification: API 5L PSL1 / PSL2; ISO 3183 L360 conformity available

- Sizes: outer diameters from 3/8" up to 30" (various SDRs/schedules available)

- Wall thickness: wide range up to 250 mm (schedules from 20 to XXS and beyond)

- Manufacturing options: hot rolled, cold drawn, thermomechanically rolled (TMR), normalized/normalizing rolled

- Finishes & coatings: plain, sand-blasted, 3LPE and other protective coatings on request

- Additional processing: cold drawing, expansion, machining and custom fabrication available

- Quality & testing: Hydrostatic testing, HIC (hydrogen-induced cracking) testing for sour service, and other mechanical/chemical testing as required

Applications

Suitable for onshore and offshore pipeline systems carrying oil, gas and water where high yield strength and reliable weldability are required. Common uses include transmission mains, high-pressure lines, and subsea pipelines when supplied with appropriate coatings and sour-service testing.

Why specify API 5L X52

X52 provides a high yield-to-weight ratio for pipeline projects requiring increased pressure capacity without excessive wall thickness. Choosing PSL2 material and additional testing (HIC, sour-service) improves assurance for demanding environments, while available coatings (3LPE) extend service life in corrosive conditions.

If you require specific dimensional tolerances, testing documentation (MTC), coating systems or heat-treatment states, please specify project requirements (PSL level, OD, wall, end-prep, coating and testing) so suppliers can provide compliant quotes.