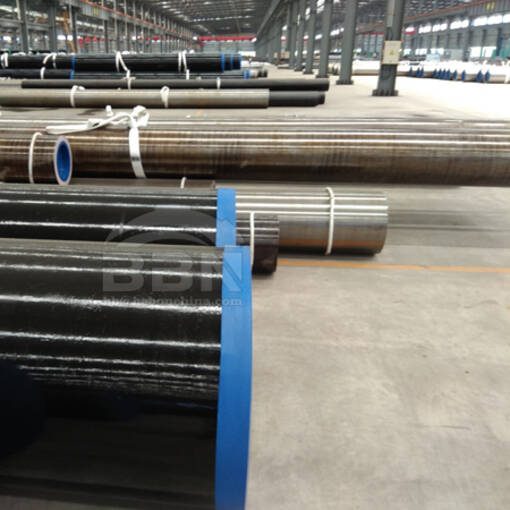

High-strength linepipe engineered for long-distance transport of gas, oil and water. Manufactured to API 5L / ISO 3183 requirements as Grade X65 (L450), this pipe is intended for pipeline systems that demand elevated yield and tensile properties and enhanced resistance to sour and hydrogen-rich service conditions.

Key features

- Conforms to API 5L Grade X65 (ISO 3183 L450) with minimum yield around 65,000 psi and typical minimum tensile around 77,000 psi (verify required values on purchase documents).

- Available to both PSL1 and PSL2 product specification levels; PSL2 includes additional testing and tighter controls for critical applications.

- Offered in seamless and welded forms (ERW, welded) with a range of end preparations: plain end, bevelled ends and threaded or coupled options.

- HIC (Hydrogen Induced Cracking) tested for hydrogen embrittlement resistance; suitable for cryogenic and hydrogen-rich environments where specified.

- NACE / sour-service compliant options available (supplied to applicable NACE TM/MR specifications on request).

- Wide nominal bore range (from small bores around 3/8" up to ~30") and wall thicknesses that can be supplied to heavy schedules (up to ~250 mm where manufacturing allowances permit).

Typical applications

- Onshore and offshore oil & gas transmission pipelines

- Injection and gathering lines

- Sour service and hydrogen service pipelines where NACE/HIC resistance is required

- Water transmission and high-pressure fluid transport

Ordering guidance

When specifying API 5L X65 pipe, provide the following to ensure correct supply:

- Product specification level (PSL1 or PSL2)

- Seamless or welded (ERW) construction

- Outside diameter and nominal bore

- Wall thickness or schedule (or exact mm thickness)

- End finish (bevel, plain, threaded/coupled)

- Required additional tests/certifications (HIC, NACE, hydrotest, PMI, material certificates)

Contact your supplier with project requirements (pressure, temperature, sour/hydrogen exposure) so material selection, heat treatment and testing can be confirmed against applicable standards.

Product Details

Harmonized commodity

Country of origin:

India

Industrial sector: