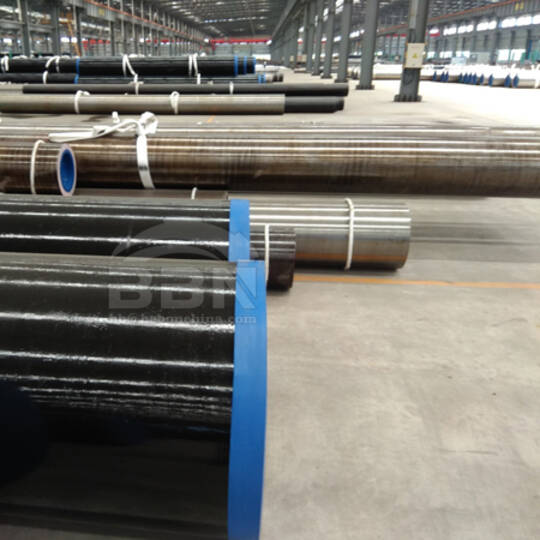

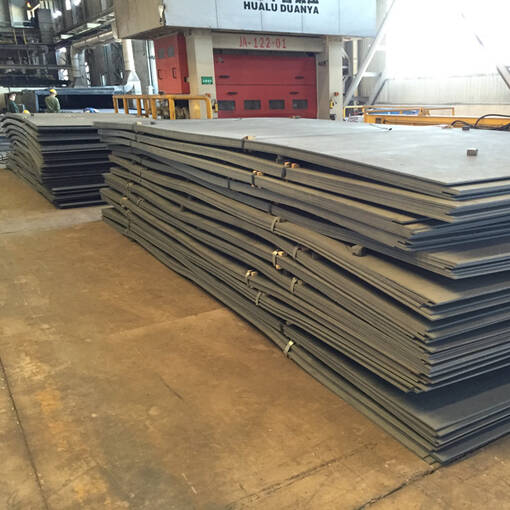

High-strength API Spec 5L line pipe in grade X42 (L290) engineered for oil & gas pipeline transmission and other demanding piping systems. Offered to meet API Spec 5L requirements in both PSL1 (standard) and PSL2 (enhanced) levels, X42 provides a reliable balance of yield strength, toughness and weldability for long-distance pipelines.

Key features

- Grades: X42 (L290) — available under PSL1 and PSL2

- Manufacturing types: Seamless (SMLS), ERW, SAW (LSAW, SSAW)

- Typical size ranges: 1/2" to 40" (seamless); 1/2" to 24" (ERW); 16" to 60" (LSAW)

- Wall thickness / schedules: SCH 10, SCH 20, SCH 40, SCH STD, SCH 80, SCH XS, SCH XXS, SCH 120, SCH 160

- Lengths: random 5–12 m, fixed 20 ft (6 m) and 40 ft (12 m)

- End finishes: beveled or plain; protection with plastic or steel caps

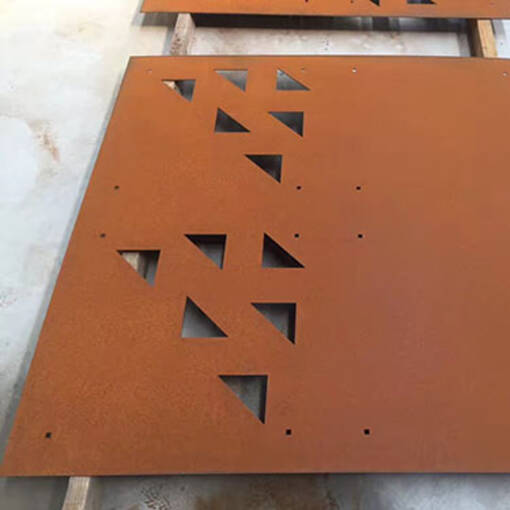

- Coatings and internal protection: 3PE, FBE, black painting, varnish; options for CRA cladding or lining

Mechanical and metallurgical overview

- Minimum yield strength: approximately 290 MPa (42,100 psi)

- Typical tensile strength: approximately 415 MPa (60,200 psi)

- Minimum elongation: ≈ 21% (depending on product form and PSL level)

- Delivery conditions: rolled (R), thermomechanically rolled/formed (M), normalizing (N), quenched/tempered or quenched (Q) — specific conditions depend on PSL and product form

- Chemical composition and mechanical property limits differ between PSL1 and the more stringent PSL2 and vary by manufacturing method (welded vs seamless)

Applications

- Oil and gas transmission pipelines (onshore trunklines and gathering lines)

- Water transmission and industrial piping where higher strength and toughness are required

Supply and ordering

- Available in multiple manufacture routes, coatings and end-preparations to match project specifications

- For quotations and project enquiries, submit an RFQ with required grade (PSL1/PSL2), pipe form (seamless/ERW/LSAW/SSAW), dimensions (OD × wall), length, coating and any testing/certification needs.