A high-strength chromium-molybdenum alloy structural steel supplied to GB and EN standards for demanding engineering applications. Offered to meet GB/T 3077 as 42CrMo and to the European EN 10083-3 standard as 42CrMo4, this grade combines high strength, good hardenability and toughness with low quench distortion and strong long-term creep and fatigue resistance after appropriate heat treatment (typically quenching and tempering).

Key features

- High tensile strength and yield strength after quench & tempering

- Good hardenability for larger cross-sections with uniform properties

- Good toughness and resistance to tempering brittleness

- Stable dimensional performance with low distortion on quenching

- Good high-temperature creep strength and long-term strength

Typical product forms

- Round bars and rods

- Forgings and shafts

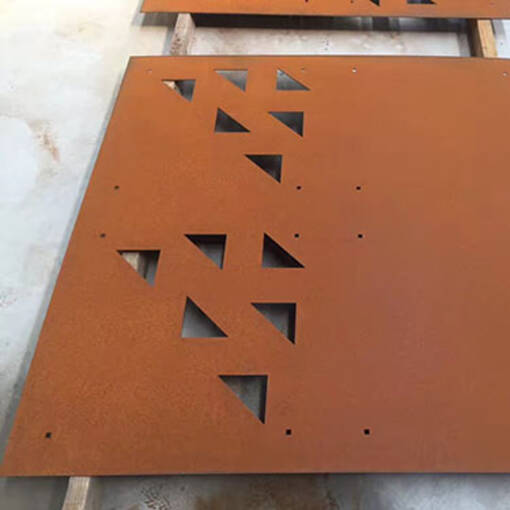

- Machined components and finished parts

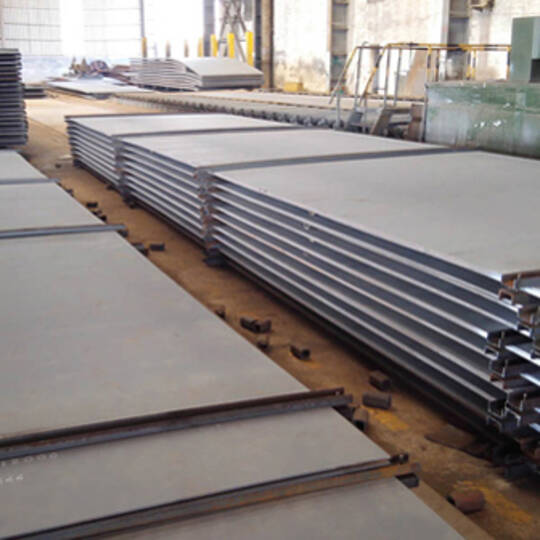

- Plates and blanks for further processing

Common applications

- Heavy-duty gears and gear blanks (locomotive traction, transmission gears)

- Large axles, heavily loaded connecting rods and shafts

- Pressure-vessel components and high-strength forgings

- Oilfield drill pipe joints and fishing tools (shallow to moderate depths)

- Large and medium plastic and metal molds where higher strength and toughness are required

Processing and heat treatment

- Best performance achieved by quenching and tempering to the required hardness/strength level

- Good hardenability allows thicker sections to be heat treated with uniform properties

- Suitable for machining, forging and controlled cooling processes

Compliance and equivalents

- Chinese standard: GB/T 3077 (42CrMo)

- European equivalent: EN 10083-3 (42CrMo4)

If you require specific supply forms, chemical analysis certificates, mechanical property ranges, or heat-treatment conditions, request a technical datasheet and supply specification to ensure the delivered material meets your application requirements.