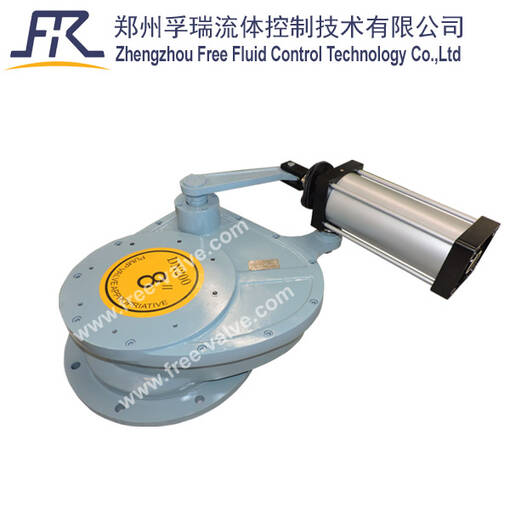

Designed for reliable, low-residence discharging and sampling from the bottom of reactors, tanks and process vessels, this manual-operation tank-bottom angle valve (bottom flush / slurry angle valve) provides fast, dead-space-free draining and feed control. The valve can be welded directly to the vessel or installed using the bottom flange, and is available with flange connections meeting ASME standards.

Key features

- Integrated-body construction for robust use in industrial service

- Disc opens into the tank for thorough discharge; available outlet angles: 45°, 50° and 90°

- Rotation-resistant stem guidance to ensure straight-line stem motion and prevent twisting

- Wear-resistant protection plate and cemented-carbide (or tungsten-coated) sealing faces for superior erosion and corrosion resistance

- Auxiliary line sealing to improve overall seal reliability

- Designed for easy installation either welded or flange-mounted at the tank bottom

Technical specifications

- Flange / design standard: ASME

- Pressure classes: Class 150 – Class 300

- Size range: DN50 – DN350 (NPS 2 – NPS 14)

- Materials: carbon steel, stainless steel (sealing faces: alloy / carbide)

- Connection type: flange

- Maximum working temperature: ≤ 425 °C

- Actuation options: manual (handwheel), pneumatic, electric

- Sealing surface: overlaid cemented carbide or tungsten coating

- Pressure testing standards: GB/T13927, API 598

Typical applications

Widely used across heavy industries where full drainage and minimal dead space are required, including petrochemical, alumina and steel plants, polymer and mining operations, pharmaceutical and fine-chemical production, and mineral processing.

Ordering notes

Specify outlet angle (45° / 50° / 90°), size (DN/NPS), pressure class (150 / 300), body material (carbon steel / stainless steel), sealing face option (carbide / tungsten coating) and preferred actuation method (manual / pneumatic / electric) when requesting a quote or placing an order.