Magnetron sputtering systems are vacuum deposition systems designed to apply high-quality metallic and dielectric coatings onto various substrates. This technology offers fast, controlled deposition at relatively low process temperatures, enabling work on heat-sensitive materials (plastics, glass, fine metals, wafers, etc.).

Key Features

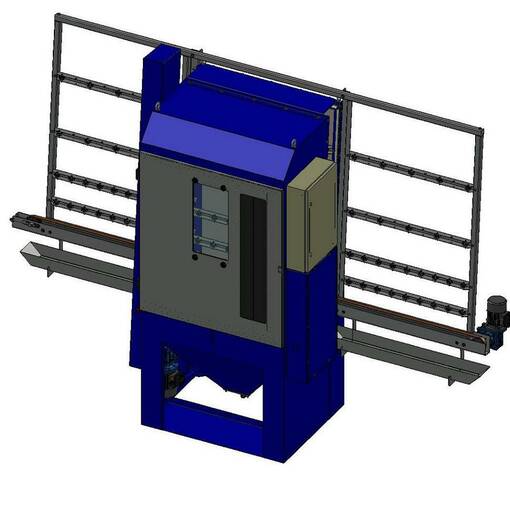

- Technology: magnetron sputtering in a vacuum chamber for physical vapor deposition (PVD).

- Stable and reproducible operation, suitable for production and for research and development.

- Low heat transfer to the substrate, reducing deformations and thermal damage.

- Simple handling and accessible maintenance; possibility of automation and integration into production lines.

- Configuration options: different chamber sizes, rotary or flat supports, DC or RF power supply, and possibility of multiple targets (targets) for composite layers.

Common applications

- Decorative and protective coatings on plastic and metal components.

- Reflective and optical layers for lenses and photonic elements.

- Metallization of packaging and films for packaging.

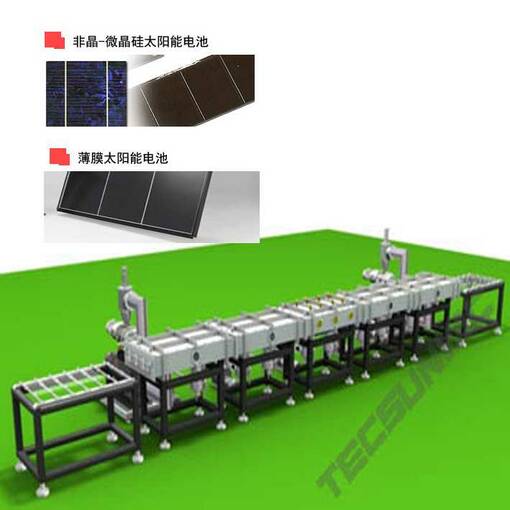

- Functional coatings in electronics (contacts, EMI shielding, conductive layers) and solar panels.

- Laboratories and pilot plants for development of coating processes.

Commercial advantages for B2B customers

- Flexibility to adapt processes and materials to production requirements.

- Improvement of functional and aesthetic performance of parts through uniform and adherent layers.

- Scalability: equipment for prototyping, medium-scale production and high-performance lines.

- Support for process development and parameter optimization (target material, power, working pressure, deposition time).

What to request when requesting a quote

To provide an accurate offer, specify:

- Type and maximum size of the substrate (material, dimensions, shape).

- Type of coating desired (metal, dielectric, target thickness).

- Performance requirements (uniformity, deposition rate, adhesion, maximum substrate temperature).

- Production needs (output per hour/day, number of pieces per batch).

- Power supply preferences (DC, pulsed DC, RF) and whether multiple chambers or load-lock are required.

Associated services (optional)

- Installation and commissioning at the site, operator training, supply of critical spare parts and maintenance contracts.

If you need more technical information or a customized proposal, provide the parameters indicated above so we can prepare specifications and delivery times tailored to your project.

Product Details

Country of origin:

China

Industrial sector: