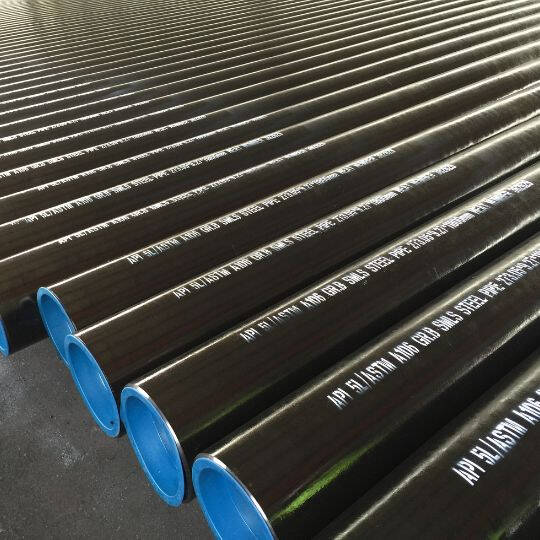

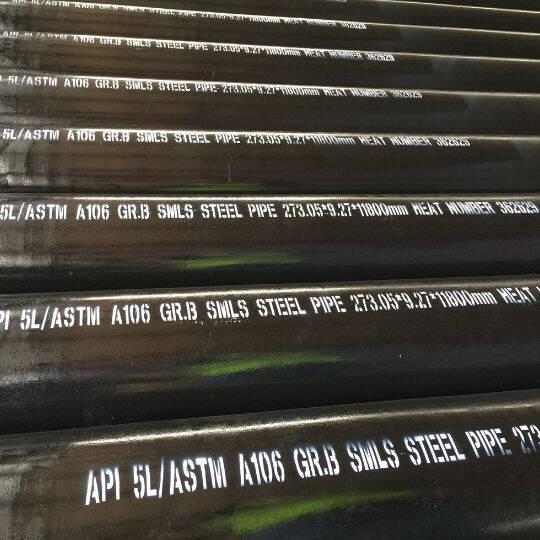

High-performance steel linepipe engineered for the transport of oil and gas in onshore and offshore pipeline systems. Manufactured to industry production grades with defined material, mechanical and testing requirements, these pipes are suitable for trunk lines, flowlines and other hydrocarbon transmission applications.

Key features

- Production grades: available in PSL 1 and PSL 2 (PSL 2 provides more stringent chemical, mechanical and testing controls and traceability).

- End preparation: nominal pipe sizes under 2" may be supplied with plain or bevelled ends; sizes greater than 2" are typically supplied bevelled to facilitate butt welding.

- Wall thickness / schedules: commonly supplied in Schedule 40 and Schedule 80 wall thicknesses to match pressure and structural requirements.

- Compatibility: designed for welded pipeline construction (butt welding) and standard fabrication workflows used in oil & gas projects.

Ordering guidance for buyers

Specify the following when requesting quotes or issuing purchase orders: production grade (PSL 1 or PSL 2), nominal diameter, required wall thickness or schedule, end preparation (plain, bevelled), required length (single random, double random or cut length), and any coating/inspection or testing requirements (e.g., hydrostatic test, nondestructive testing, mill test certificates). For critical projects, confirm the exact material standard and acceptance criteria with the supplier.

Applications

Well suited for long-distance oil and gas transmission mains, distribution lines, flowlines and other pipeline infrastructure where standardized, weld-ready steel pipe is required.

Supply note

Large quantities are available in common schedules (Sch 40 and Sch 80). Contact your supplier with full specification details to ensure delivery of the correct grade, dimensions and end preparation for your project.