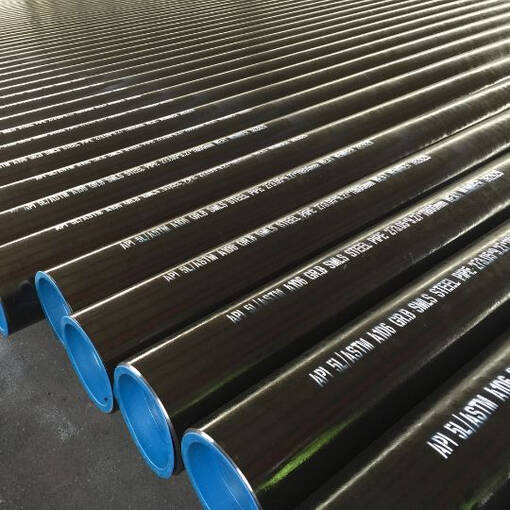

Seamless oilfield casing and tubing produced to API 5CT requirements for well construction and production. These tubulars are manufactured from seamless steel, threaded and coupled at both ends (threaded-and-coupled, T&C) to allow secure make-up in well strings. Casing is used to line the wellbore and isolate formations; tubing runs inside the casing to convey produced fluids to surface.

Key features

- Manufactured to API 5CT standard for casing and tubing materials and mechanical properties.

- Seamless steel construction for high axial and radial strength in downhole conditions.

- Common API grades available for well applications (examples used in the industry include J55, K55, N80, L80, C90, T95, P110).

- End connections: threaded and coupled (API-style threads/couplings).

- Typical tubing sizes are under 4" OD; casing sizes are larger and selected per well design.

- Lengths supplied in standard ranges (industry length classes R1, R2, R3) — R2 and R3 are the most commonly used.

- Internal/external corrosion protection options, including corrosion-resistant alloy (CRA) linings or coatings for environments where corrosion or erosion is a concern.

Typical applications

- Production tubing conveying oil and gas from the reservoir to surface

- Various casing strings: conductor, surface, intermediate, and production casing to support the wellbore and isolate zones

- Workover and intervention operations where reliable make-up and tensile capacity are required

Quality and testing

- Supplied with material certificates and standard testing per API 5CT (chemical analysis, mechanical testing). Additional NDT, hardness, or special coatings can be supplied upon request.

Ordering options

- Specify API grade, outer diameter, weight/ft (or wall thickness), length class (R1/R2/R3), end finish (pin/box thread and coupling type), and any corrosion protection or special heat treatment required. Custom sourcing and inspection plans are available for large or project-based orders.

Contact your procurement representative with detailed well specifications (required OD, weight, grade, length class, and connection type) to receive a tailored quotation and lead time.

Product Details

Harmonized commodity

Country of origin:

United States

Industrial sector: