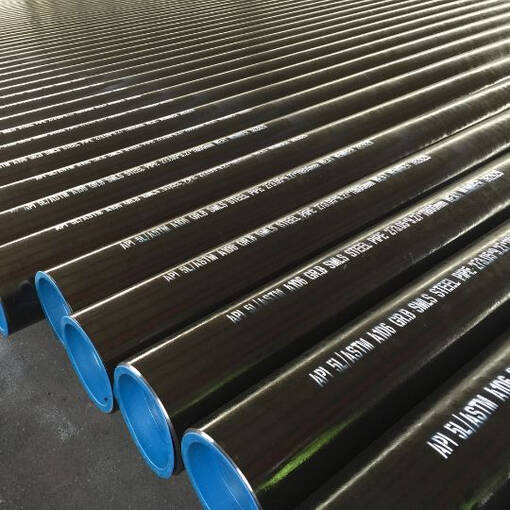

Seamless, cold‑drawn low‑carbon steel tubes manufactured to ASTM A179 / ASME SA179 for tubular heat exchangers, condensers and similar heat‑transfer equipment. These tubes are specified for applications requiring tight dimensional control, smooth internal surfaces and good formability for high‑temperature gas and liquid service.

Key features

- Material: Seamless cold‑drawn low‑carbon steel produced to ASTM A179 / ASME SA179 requirements.

- Manufacturing: Cold‑drawn (seamless) for improved dimensional accuracy and surface finish compared with hot‑finished products.

- Size range: NPS 1/8" up to 36" (consult for intermediate sizes).

- Wall thickness / schedules: Available in common schedules (SCH 10, SCH 40, SCH STD, SCH 80, SCH XS through SCH 160 and SCH XXS) to meet pressure and thermal requirements.

- End preparations: Plain, beveled, or other end treatments per customer specification.

- Lengths: Single random length (SRL), double random length (DRL) and fixed lengths (commonly 20 ft / 6 m and 40 ft / 12 m); custom lengths on request.

- Surface protection: Options include FBE or 3PE epoxy coatings, black paint, varnish, anti‑rust oil and galvanized finish (zinc coatings available — example weight 550 g/m²), as required for storage and service.

- Packaging: Supplied in protective bundles (hexagonal or round) secured with steel strapping and protective end covers to prevent damage during handling and transport.

Quality & supply

- Supplied to ASTM A179 / ASME SA179 dimensional and material requirements; special dimensions and tolerances can be manufactured to customer specifications.

- Inspection and testing available on request (dimensional inspection, hydrostatic testing and routine material tests as per the standard). Certificates and test reports can be provided with shipment.

Typical applications

- Tubular heat exchangers and condensers

- Petrochemical and chemical process equipment

- Mechanical pressure equipment

- Marine and offshore systems

- Food processing and pharmaceutical heat‑transfer equipment

Contact your supplier with required sizes, wall thickness, end preparation and coating preferences for a quotation and lead‑time details.

Product Details

Harmonized commodity

Brand:

BBN Steel

Country of origin:

China

Industrial sector:

Unit type:

Metric Ton