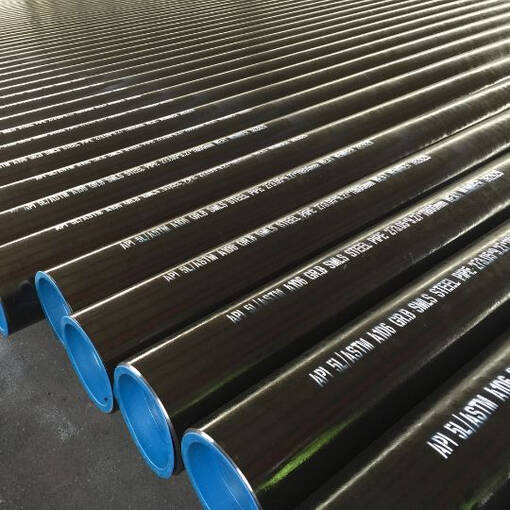

A three-layer external corrosion protection system applied to steel pipe: a fusion-bonded epoxy (FBE) primer on the steel, an intermediate adhesive layer, and a polyethylene (PE) or polypropylene (PP) outer jacket. The coating is applied to the pipe exterior and provides long-term protection against soil and atmospheric corrosion while also delivering mechanical and abrasion resistance during handling and installation.

Key features and benefits

- Durable corrosion protection: multi-layer system designed for long-term service life in buried and exposed pipeline installations.

- Mechanical resistance: PE/PP outer layer resists impact, abrasion and third‑party damage during transport and installation.

- Strong adhesion: FBE primer plus adhesive layer ensures reliable bond to the steel substrate and reduces undercutting.

- Field-friendly: compatible with standard field joint coating and repair systems, enabling on-site joint protection.

- Quality assurance: manufactured and tested to recognized pipeline coating standards to ensure consistent coating thickness, adhesion and continuity.

Typical applications

- Transmission pipelines for oil and gas

- Water and district heating mains

- Industrial process and distribution pipelines

- Any onshore pipeline project requiring external corrosion protection

Supply and customization

Products are produced to project specifications and can be supplied in a range of diameters, wall thicknesses and steel grades on request. Coating thicknesses, testing regimes (holiday testing, thickness measurement, adhesion testing) and documentation are provided in accordance with applicable pipeline coating standards (for example ISO 21809-3, DIN 30670, NACE SP0394) and customer requirements.

If you need project-specific data (available diameters, steel grades, coating thickness ranges, test certificates or handling/installation guidance), include your specifications and service conditions so an accurate offer can be prepared.