-

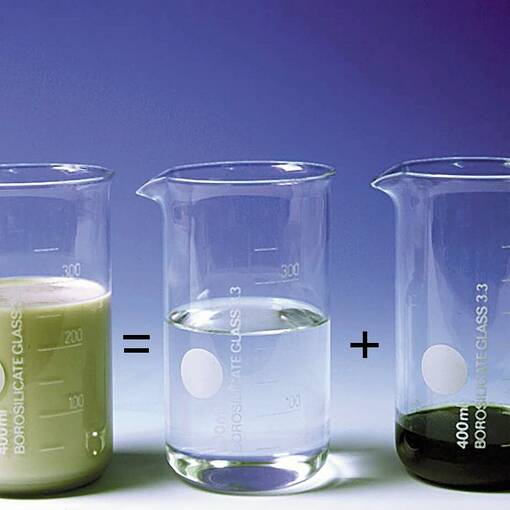

Heavy-duty, corrosion-resistant self-priming centrifugal pump engineered for aggressive chemical handling. The wet-end is molded from reinforced polypropylene (FRPP / CFR-PP) to combine high mechanical strength with broad chemical compatibility for acids, alkalis and saline solutions.

-

Self-priming design with integrated liquid suction chamber, storage chamber, gas–liquid separation chamber, reflux hole and check valve, enabling reliable dry-start suction performance (typical suction lift: 3–4 m).

-

Leak-minimizing construction: anticorrosion mechanical seal and integrated impeller-and-shaft assembly reduce leak paths and simplify maintenance. Pump can be close-coupled directly to the motor or delivered for shaft-coupling arrangements.

-

Operating conditions: suitable for pumped fluid temperatures from -10°C to 90°C. Intended for a wide range of low- to moderate-temperature chemical transfer duties.

-

Typical industrial uses: chemical processing, pharmaceuticals, food processing (for compatible fluids), metallurgy, environmental and wastewater treatment, inorganic salts production and other corrosive-service applications.

Why specify this pump:

- Corrosion resistance for long service life in aggressive chemistries

- Self-priming capability for suction-line flexibility and reduced auxiliary equipment

- Simplified maintenance with integrated impeller/shaft and robust mechanical seal

- Flexible coupling options to match existing motor/drives

Note: Confirm required hydraulic performance (flow, head, NPSH), connection sizes and motor specification with your supplier to ensure the selected model (e.g., 50FPZ-20) meets your system requirements.