AISI 430 (Alloy 1.4016) is a cost-effective ferritic chromium stainless steel designed for applications where moderate corrosion resistance, good formability and magnetic properties are required but high strength and nickel-alloyed corrosion resistance are not necessary. It contains chromium as the chief alloying element (ferritic structure) and is commonly selected for uses exposed to basic or mildly corrosive environments.

Key features

- Ferritic stainless steel with chromium content for basic corrosion resistance and good resistance to atmospheric corrosion and many chemical environments at low concentrations.

- Economical alternative to austenitic stainless grades where high corrosion resistance or non-magnetic behaviour is not required.

- Limited weldability and lower plasticity compared with austenitic stainless steels — standard welding procedures are generally not recommended without special controls.

- Not resistant to strong reducing acids: specifically unsuitable for environments containing hydrochloric acid, hydrofluoric acid or concentrated sulfuric acid.

Typical resistance (suitable media)

Water, steam, alcohols, calcium chloride, nitrates, dilute nitric acid, many food products and fats, acetone, benzene, esters, ethers, glycols, glycerine, adhesives, urea and some substances encountered in fuel production. Evaluate compatibility for each specific concentration and temperature before use.

Mechanical and physical properties (typical ranges)

- Tensile strength (Rm): 400–630 MPa

- Yield strength (Re): > 240 MPa

- Elongation (A): > 20%

- Modulus of elasticity (E): ~220 GPa

- Hardness (HB): < 200

- Thermal conductivity: ~25 W·m⁻¹·K⁻¹

- Specific heat: ~460 J·kg⁻¹·K⁻¹

- Electrical resistivity: as supplied (refer to mill certificate for exact value)

Applications

Commonly used in sectors such as: oil & gas (non-critical tanks and fittings), food processing and handling equipment, textile machinery components, automotive trim and parts, household appliances and general-purpose equipment where moderate corrosion resistance and magnetic properties are acceptable.

Notes for procurement and fabrication

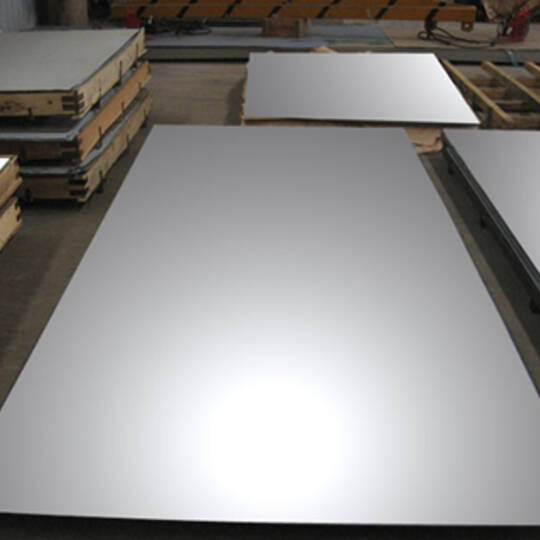

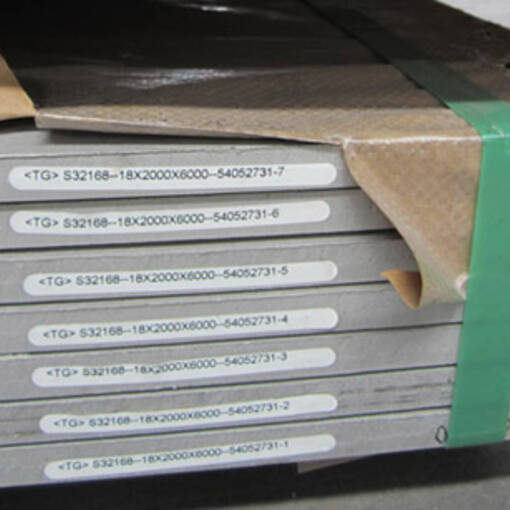

- Specify the desired product form (sheet, coil, plate, bar or strip), surface finish and tolerances when ordering.

- Because of limited weldability and different mechanical behaviour from austenitic grades, consult your fabricator or materials engineer for joining, forming and finishing recommendations.

- Request material certificates (chemical and mechanical test reports) for critical applications to verify compliance with required standards.