Company specialized in PVD metallization equipment and industrial production lines designed for applications in photovoltaic energy, functional glass, automotive, fiber, and roll-to-roll processes. The solutions are designed for B2B customers who require robust equipment, automation options, and process control to deposit metallic and functional layers using various vacuum technologies.

Main equipment and lines offered:

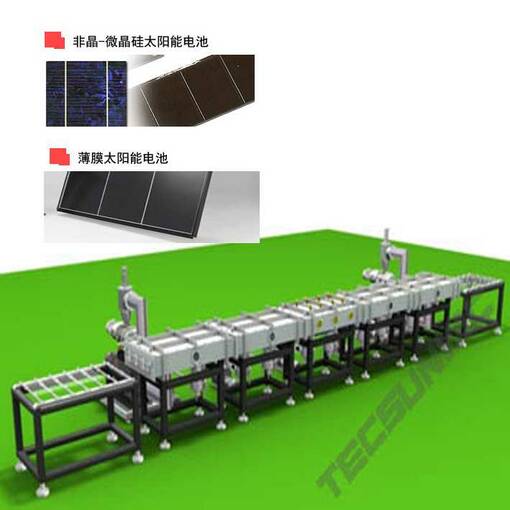

- Complete lines for the manufacture of amorphous silicon photovoltaic solar cells (turnkey lines for series production).

- Magnetron sputtering metallization machines for multiple applications.

- Electron beam (e-beam evaporation) metallization machines for vacuum evaporation deposition.

- Discharge arc (poly-arc / cathodic arc) metallization machines for conductive and decorative coatings.

- Magnetron sputtering lines for low-emissivity (low-E) glass or ITO-coated glass.

- Sputtering machines for coating wheels and automotive parts.

- Rollers for fiber feeding and wire metallization.

- Roll-to-roll sputtering rollers for DC and MF (medium frequency) flexible substrates.

- Evaporation equipment for vapor deposition metallization processes.

- Vacuum pumps and auxiliary components for industrial vacuum installations.

Relevant features for industrial buyers:

- Compatibility with batch and continuous (roll-to-roll) processes.

- Process control and automation options for reproducibility and labor savings.

- Adaptability to different substrates: glass, polymers, metal, fiber, and semiconductors.

- Typical applications: conductive layers (ITO, metals), optical and thermal coatings, decorative and corrosion protection, and processes for photovoltaic manufacturing.

- Supply of complete lines and components (vacuum systems, power sources, deposition heads).

Why choose these solutions (from a B2B perspective): greater process flexibility, the possibility of supplying integrated lines for industrial production, and compatibility with scaling requirements for high-volume production. For detailed specifications, available configurations, and customization options, request the technical sheet and plant layout plans to evaluate integration into your production line.