A horizontal axial-flow forced-circulation pump engineered for evaporative crystallization and high-flow, low-head circulation in chemical and process plants. The FJX series uses an impeller that generates axial thrust along the pump shaft to move liquid directly along the shaft direction, making it especially effective for forced circulation in evaporators, crystallizers and cooling loops where steady, high-volume flow is required.

Key features

- Horizontal axial-flow design (horizontal shaft) optimized for large flow/low head duty

- Impeller-driven axial thrust produces continuous suction and discharge along the pump axis

- Intended for forced circulation to increase equipment throughput and heat-transfer coefficients

- Suitable for handling process media and slurries encountered in evaporation and crystallization systems

How it works

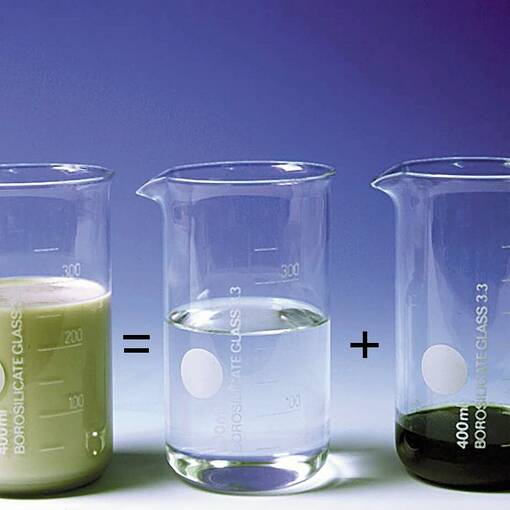

- The rotating impeller blades are set at a spiral angle to the shaft. As the impeller turns, it produces axial thrust that pushes liquid out through the discharge.

- Discharge causes a local pressure drop at the inlet, drawing makeup liquid into the impeller. Continuous rotation sustains constant intake and discharge, enabling steady forced circulation.

Typical applications

- Evaporative crystallization and forced circulation in phosphoric acid and phosphate fertilizer plants

- Sodium aluminate circulation in Bayer aluminum oxide plants

- Evaporation and concentration in diaphragm caustic soda production (media containing NaCl)

- Vacuum salt and mirabilite (Na2SO4) evaporators

- Hydrometallurgical evaporating crystallizers (e.g., copper sulfate, nickel sulfate)

- Alkali processing: ammonium chloride, calcium chloride recovery and crystallizers

- Paper mill concentrators, power plant flue gas desulphurization and related chemical process loops

Operational benefits for B2B users

- Improves evaporator/crystallizer throughput and heat-transfer performance via forced circulation

- Designed for continuous operation in process environments where steady axial flow is required

- Suitable for integration into existing evaporator/crystallizer circulation systems

Ordering & identification

- Series/MPN: FJX

- Model example: FJX-250

For specification-driven purchases, provide process duty data (flow rate, required head, liquid density/viscosity, temperature, solids content and corrosivity) so suppliers can confirm materials, clearances and impeller configuration appropriate for your application.