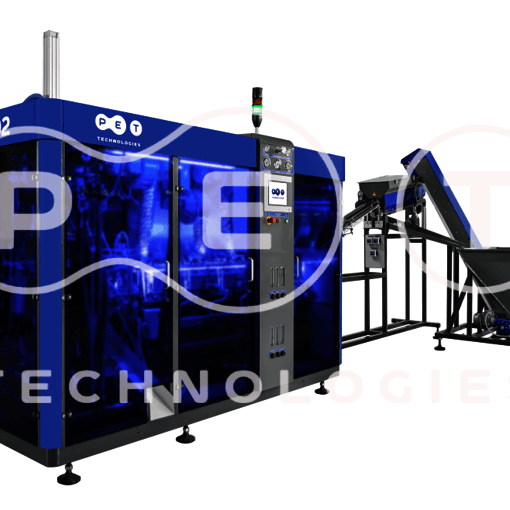

Automatic stretch-blow molding system engineered for mid‑to‑large PET containers (3.0–10.0 L). The machine converts PET preforms into finished bottles using stretch blow molding technology and is intended for integration into bottling and liquid‑packaging production lines.

Key features

- Designed production range: 3.0–10.0 L PET containers

- Output: up to 1,600 bottles per hour

- Dual independent blowing units: two units operate alternately to produce two different bottle formats in turns, increasing format flexibility and line utilization

- Certifications: CE certified and compliant with HACCP requirements for food hygiene

Benefits

- Flexible format management: alternating blowing units let you run two bottle formats sequentially without stopping the entire line

- Suitable for food‑grade and other liquid packaging applications thanks to HACCP conformity

- Compact solution for medium‑throughput operations requiring reliable, automatic molding of large PET containers

Typical applications

- Production of large PET containers used for packaged water, edible oils, detergents and other liquid products (where HACCP compliance is required)

Notes

- The machine accepts PET preforms and produces finished stretch‑blown bottles. For detailed technical data, plant layout, utilities and tooling options, request the full technical datasheet and factory acceptance details.

Product Details

Harmonized commodity

Country of origin:

Austria

Industrial sector:

Model:

APF-5