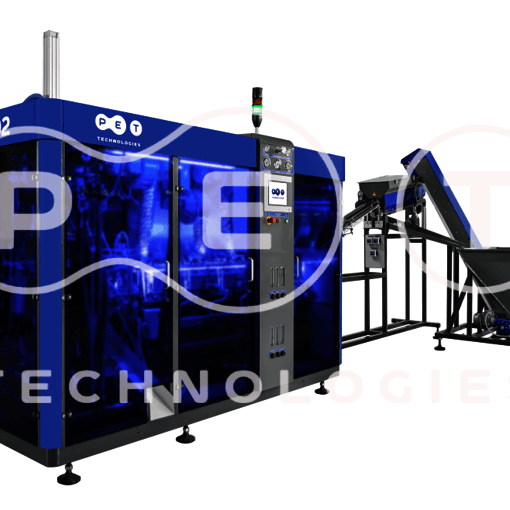

Automatic blow-moulding system engineered for production of PET water-kegs and 4–5 gallon water-cooler bottles (both one-way and returnable formats). Built to deliver stable, low-volume production runs with an output capacity of up to 500 bottles per hour.

Key features and benefits:

- Application: Designed specifically for PET kegs and 4–5 gallon water-cooler bottles (single-use and returnable).

- Capacity: Nominal output up to 500 bottles per hour, suitable for small-to-medium production lines or niche packaging runs.

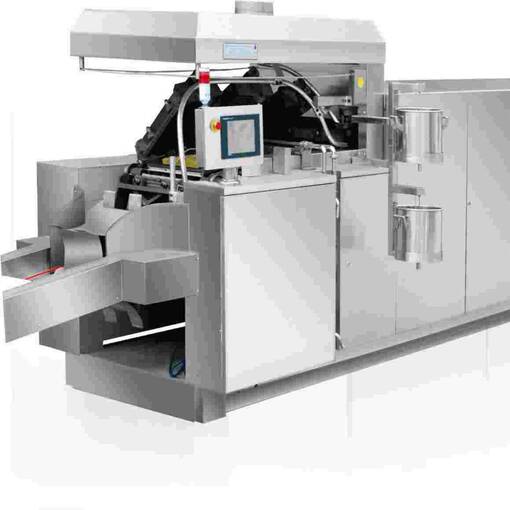

- Preform heating: Heating system configured for heavy-weight, thick-walled preforms — provides intensive, deep heating to promote uniform material distribution and strong, consistent wall thickness in finished containers.

- Quality & compliance: Supplied with CE certification and conformity to HACCP requirements, supporting food-safety and regulatory needs in beverage and water packaging operations.

Typical use cases: Production of PET water kegs and large-capacity cooler bottles for bottled-water plants, beverage producers, and contract packers requiring robust, thick-walled containers.

For exact machine specifications, tooling options, energy consumption, and integration requirements, request the full technical datasheet and production acceptance documentation from the equipment supplier.

Product Details

Harmonized commodity

Brand:

PET Technologies

Country of origin:

Austria

Industrial sector:

Model:

APF 30