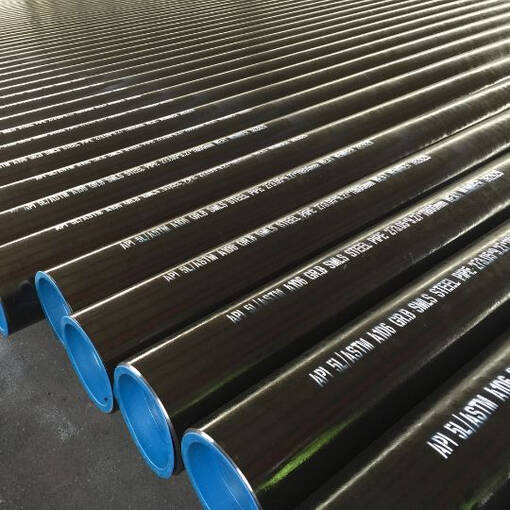

Seamless medium‑carbon steel tubes manufactured to ASTM A210 / A210M (ASME SA‑210) for boiler, superheater and high‑temperature service. Produced by a seamless process and supplied hot‑finished or cold‑finished with grade markings, these pipes are designed to meet the tensile and hardness requirements called out in the standard where applicable to the specified sizes.

Key features

- Standards: ASTM A210, A210M, ASME SA‑210

- Main grades available: Grade A1 and Grade C

- Manufacturing: Seamless (hot‑finished or cold‑finished), supplied with traceable markings

- Typical applications: Boiler tubes, superheaters, boiler flues, safe ends, arch and stay tubes and other high‑temperature boiler components

- Chemical / mechanical: Medium carbon steel with alloying (manganese, etc.) formulated for elevated temperature strength and creep resistance; mechanical properties meet ASTM A210 requirements for applicable sizes

Available sizes and options

- Nominal pipe sizes: NPS 1/8" to 36"

- Schedules: SCH 10, SCH 40, SCH STD, SCH 80, SCH XS up to SCH 160 and SCH XXS

- Lengths: Single random length (SRL), double random length (DRL), fixed lengths (20 ft / 6 m and 40 ft / 12 m)

- End preparations: plain, beveled, or as specified by purchaser

- Surface protection / coatings: 3PE or FBE epoxy coatings, black paint, varnish, anti‑rust oil, or hot‑dip galvanized (zinc coating ~550 g/m2)

Quality and supply

Pipes are manufactured to meet industry dimensional and material tolerances and can be supplied with mill test certificates (MTC) per customer requirements. Typical commercial packaging and sea/land export packing options are available. For quotation, specify grade, NPS, schedule (or wall thickness), length, end finish and any coating or testing requirements.