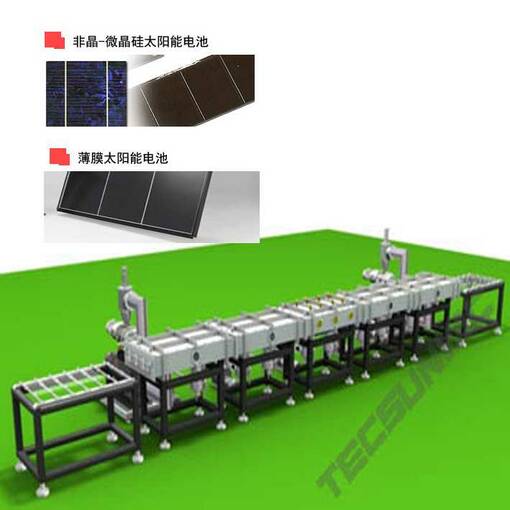

Magnetron sputter production line designed to apply metallic coatings and oxidized layers on large glass surfaces, especially Low-E glass for architecture. The system deposits functional and decorative films that improve solar insulation, reduce thermal emission, and contribute to energy savings in facades, curtain walls, high-performance windows, and decorative elements.

Main Features:

- Technology: vacuum magnetron sputter for uniform deposition on large glass panels.

- Applications: architectural glass coating (curtain walls, windows, partitions, decorative glazing) with low emissivity and thermal control properties.

- Coating Benefits: improved thermal insulation, reduction in solar heat gain, lower radiative emission, and aesthetic possibilities for architectural finishing.

- Flexibility: suitable for metallic and oxidized composite layers; allows process configuration according to the glass's optical and thermal requirements.

- Industrial Integration: designed for continuous operation and processing of large-format glass sheets with thickness and uniformity control.

- Operational Advantages: coating reproducibility, control of process parameters (pressure, sputter power, transport speed), and compatibility with subsequent laminating or tempering processes.

Services and Support (optional): the line can offer customization options according to production specifications—such as useful width, number of sputter heads, and automation—along with commissioning, operator training, and technical support as agreed.

This solution is intended for architectural glass manufacturers and processing plants requiring high-quality, high-performance Low-E coatings with capacity for integration into industrial production lines.