Insulating exothermic sleeves designed for riser and feeding of cast iron and steel parts. They combine controlled exothermic reaction with insulating materials to maintain local temperature during solidification, reducing typical defects such as porosity or unwanted reactions between molten metal and the mold.

Features and Benefits

- Maintain localized heat through exothermic reaction and insulating barrier, improving feeding and homogeneity of solidification.

- Reduce occurrence of porosity, folds, and brittle zones in the cast part.

- Prevent or minimize chemical reaction between molten metal and mold material in the feeding area.

- Compatible with a wide range of ferrous metals: steels (carbon, low/high alloy, stainless, Hadfield) and irons (gray, nodular, malleable, and alloyed).

- Suitable for multiple molding types: manual molding, pressure molding, shakeout, blow molding, sand projector molding, and explosive blow molding.

Applications

- Feeding and riser in casting of automotive parts, industrial components, and fixtures where localized thermal control is required.

- Use in sand-molded parts and processes requiring reduction of feeding defects.

Presentation and Customization

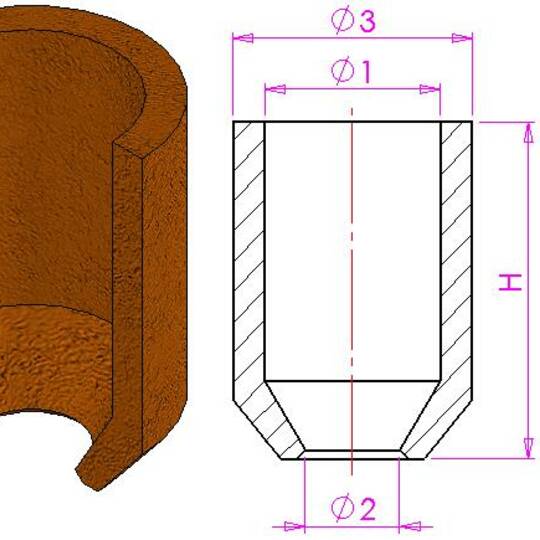

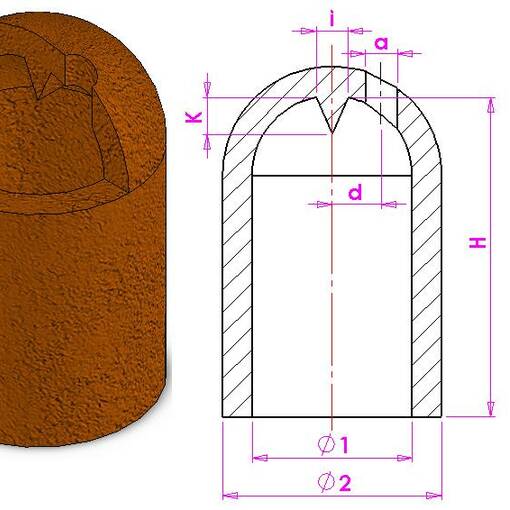

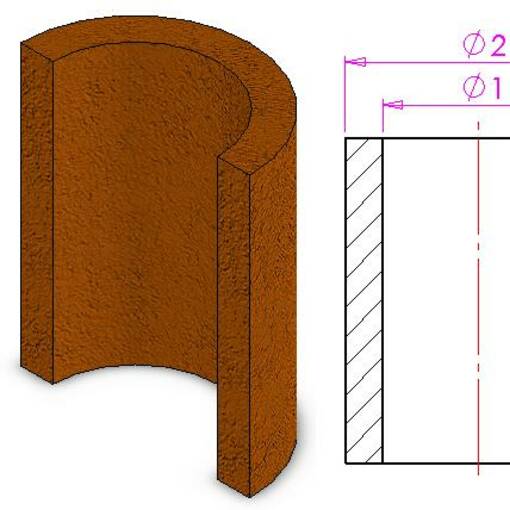

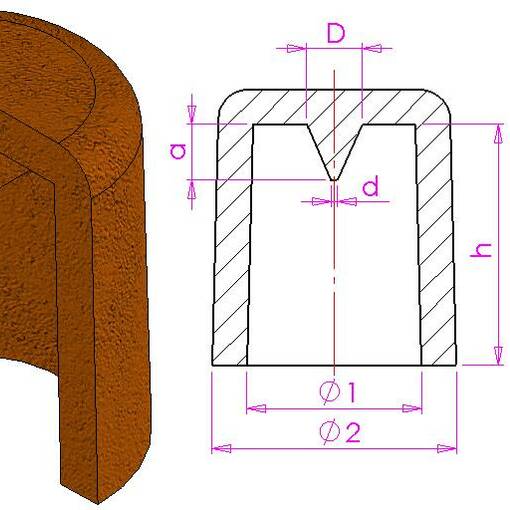

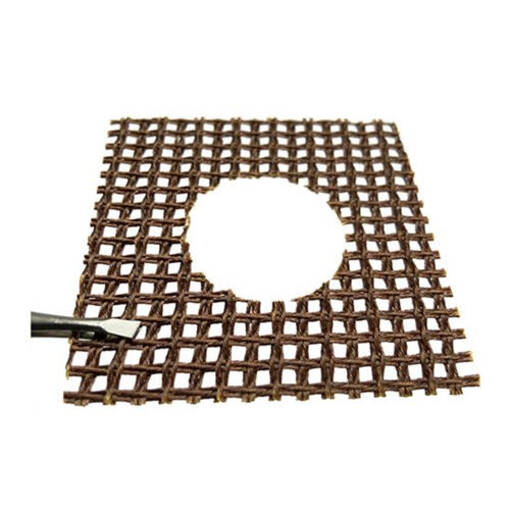

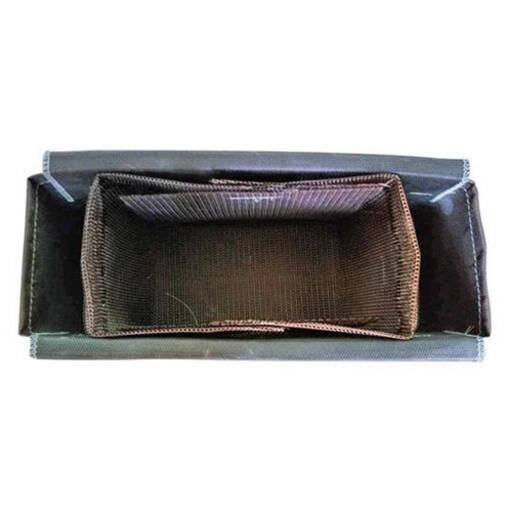

- Available in various diameters, lengths, and geometries according to customer's drawing or specification.

- Options for versions adapted to different feeding systems and mold configurations.

- Supplied in dry storage packaging; it is recommended to avoid moisture before use.

Usage Recommendations

- Position the sleeve in the feeder configuration according to the planned solidification design; ensure proper mechanical contact with the feeding system.

- Request technical data sheet and compatibility tests for critical applications or special alloys.

Product indicated for foundries seeking to improve quality of ferrous parts and optimize feeding during solidification.

Product Details

Country of origin:

Spain

Industrial sector: