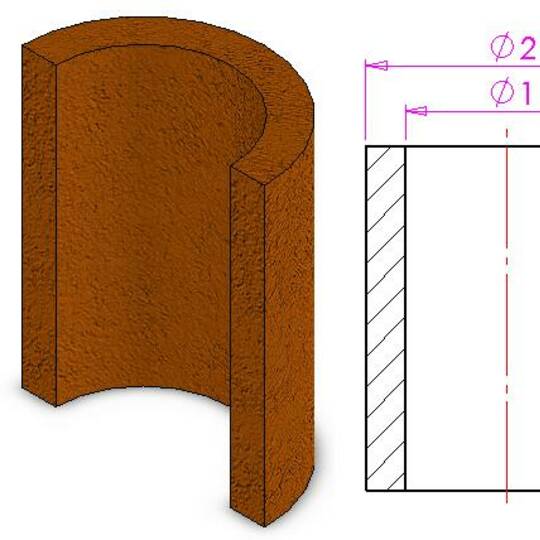

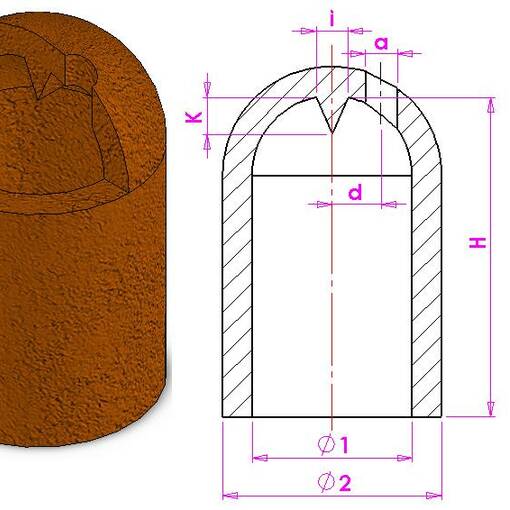

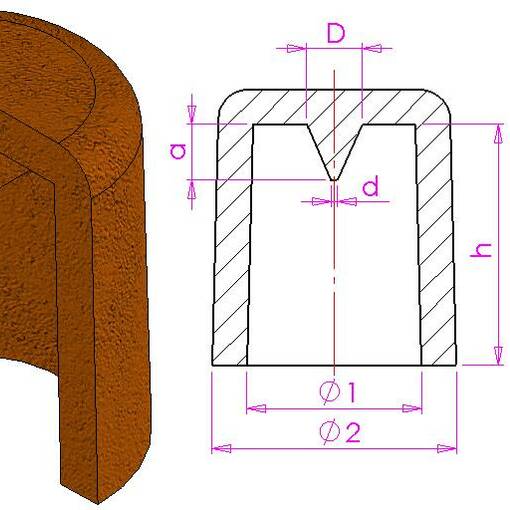

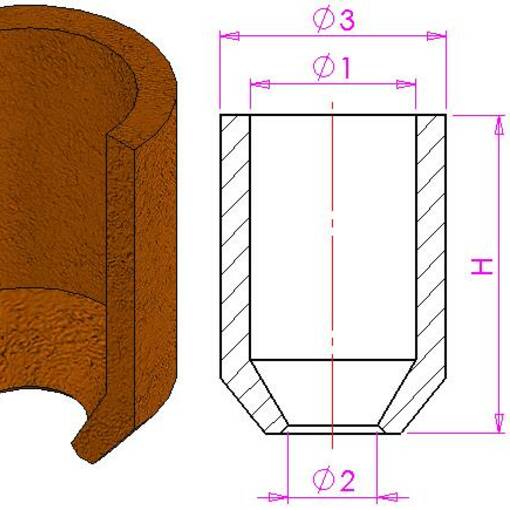

Thermal and insulating sleeves designed for feeding (alimentation) of cast parts in iron, steel and their alloys. These high-performance sleeves combine a controlled exothermic reaction with an insulating layer to regulate metal solidification and prevent typical defects in feeders.

Main Features:

- Purpose: exotic and insulating feeders (gates) for sand casting and other mold processes.

- Benefits: promote sound parts, reduce porosity and prevent metal reaction with feeder coating.

- Metal compatibility: steel (carbon, high and low alloy, stainless, Hadfield), and iron (ductile, malleable, grey, and alloyed).

- Compatible molding types: manual molding; pressure and shake-out; blow molding machine; shot blasting (projector); explosion blow molding or other sand projection systems.

- Operation: the exothermic charge generates additional heat in the feeder to delay solidification, while the insulating layer controls thermal dissipation to the environment and mold.

Recommended Applications:

- Casting of structural components and critical parts requiring efficient and controlled feeding.

- Industrial sand casting processes requiring minimization of shrinkage, porosity, and metal-coating reaction defects.

B2B Purchase Notes:

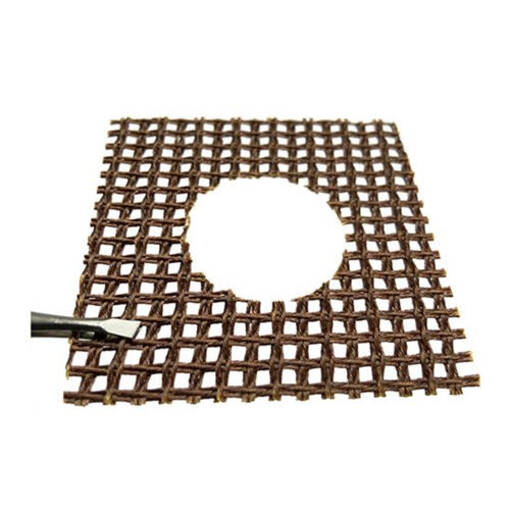

- Supplied in geometries and dimensions adapted to feeder requirements and part design; confirm technical specifications (diameter, length, shape) with your supplier when placing an order.

- Installation: must be placed to maintain thermal contact with the molten mass to ensure proper feeding; follow the mounting practices of the casting process used.

If you need detailed technical specifications (composition, standard dimensions, reaction temperatures or installation recommendations), specify to enable us to provide data or coordinate a technical quotation.

Product Details

Country of origin:

Spain

Industrial sector: