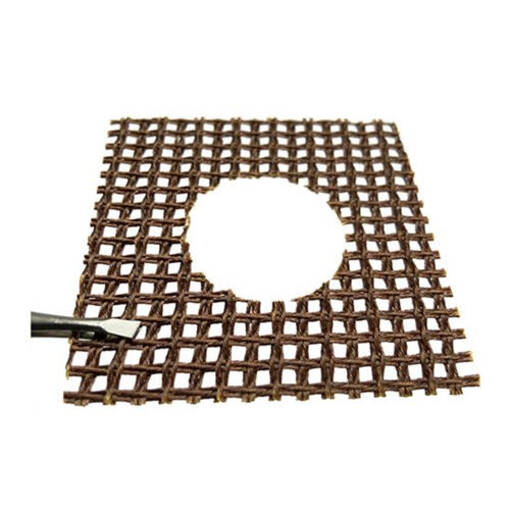

High-performance thermally active and insulating sleeves designed for riser feeding in the casting of iron, steel, and their alloys. Engineered to integrate into sand casting systems and other molding processes, these sleeves combine exothermic action with insulation to keep molten metal in the feeders and ensure controlled solidification.

Key benefits:

- Reduction of porosity and defects caused by inadequate feeding.

- Prevent reactions between molten metal and the feeding system.

- Maintain riser temperature through exothermic contribution, improving pouring continuity and directional solidification.

- Contribute to healthy and homogeneous parts, reducing reprocessing and scrap.

Applications and compatibility:

- Recommended for riser feeding in steel casting (carbon steel, high/low alloy, stainless, Hadfield) and iron (malleable, nodular, gray, high/low alloy).

- Suitable for various molding types: manual, low pressure and shake-out, blow, shot blasting, and explosive shot blasting.

Relevant technical characteristics (industrial use):

- Combined operation: exothermic contribution to prolong riser melting time and insulating layer to limit thermal losses.

- Designed for easy integration into feeding systems and standard foundry practices.

Usage recommendations:

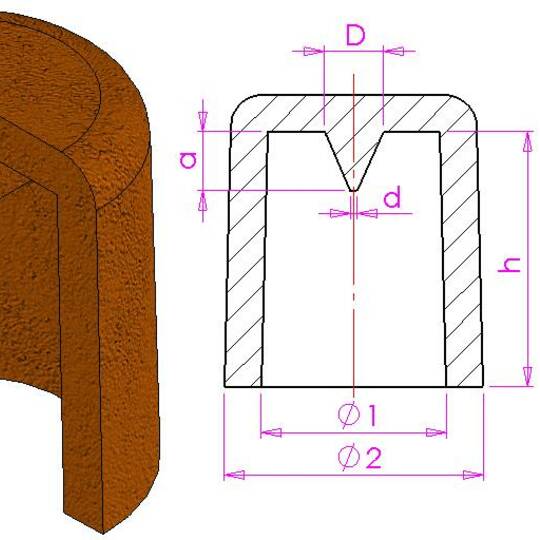

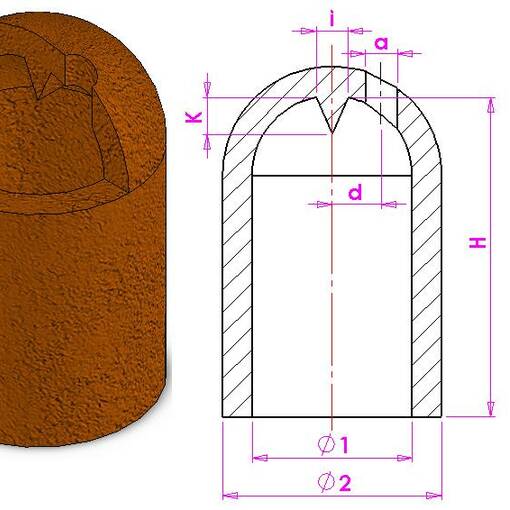

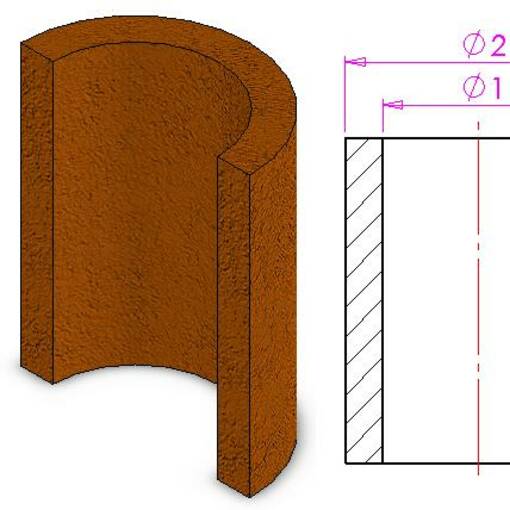

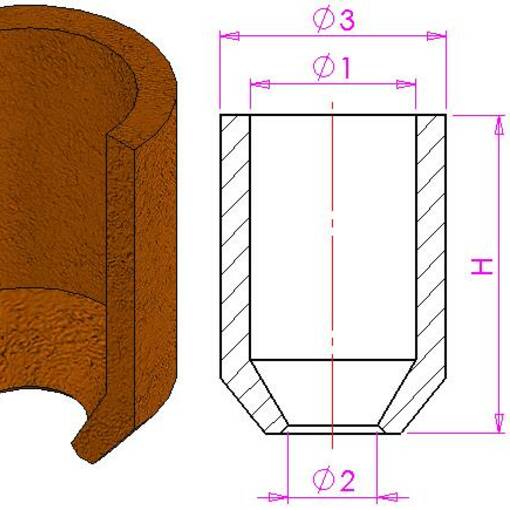

- Select the type and size of the sleeve according to riser geometry and metal to be cast.

- Integrate with good feeder design practices to ensure directed solidification.

- Follow supplier instructions for handling and installation to avoid contamination and ensure performance.

These sleeves are a practical solution for foundries requiring improved feeding and part quality in industrial ferrous metal processes.

Product Details

Country of origin:

Spain

Industrial sector: