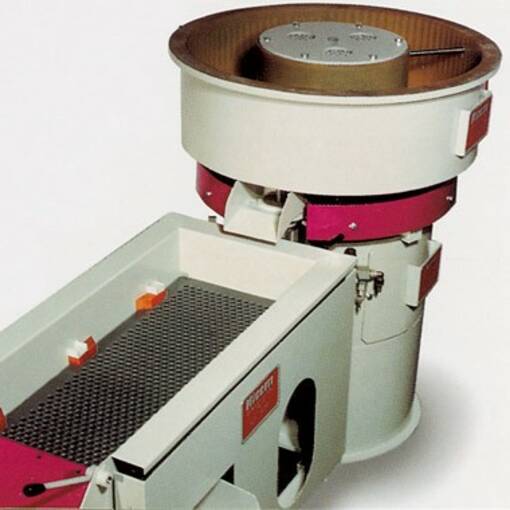

Continuous industrial shot blasting system designed for the automatic treatment of wires, bars and profiles from wire drawing. This system is intended to be integrated into production lines and ensure uniform and high productivity blasting in short periods of time.

Key features:

- Continuous operation and prepared for high production processes (ideal for wire drawing installations).

- Turbine blasting, with configurable number and power of turbines according to line speed (meters/minute), type of material and required level of cleaning.

- Treatment objectives: decaking, scaling removal and elimination of surface scales or impurities to improve adhesion in subsequent processes (painting, coating, galvanization, etc.).

- Adaptable design for cylindrical parts: possibility to work with wires, bars and tubes of different diameters in continuous passage through specific turbine positioning and power.

- Line integration: designed for series mounting within the productive installation, with feeding and output options synchronized to wire drawing speeds.

- Maintenance and spare parts supply: manufactured by a supplier with a permanent stock of parts and international presence, which facilitates support and wear parts.

Common options and accessories (according to configuration):

- Abrasive recovery and classification systems to optimize consumption and cleanliness.

- Dust filtration and extraction for environmental and safety compliance.

- Automatic control and speed regulation (PLC) and control panels adapted to the line.

- In-line inspection and measurement stations for quality control.

Main applications:

- Wire drawing mills and wire drawing lines.

- Pre-treatment prior to coating processes (painting, galvanization, varnishing).

- Cleaning and deburring of metal surfaces before mechanical or thermochemical processes.

Custom configuration:

The number of turbines, installed power and accessories are dimensioned according to the needs of each client: production speed, type and diameter of the material and the required degree of descaling. A technical evaluation is recommended to define the optimal configuration for your production line.