High-wear ceramic-lined ball valve engineered for abrasive and corrosive services. Internal components manufactured from engineering ceramics deliver exceptional hardness and wear resistance, extending service life in slurry, powder and particle-laden media while providing reliable shut-off and proportional throttling control.

Key features

- Engineering-ceramic sealing and wetted parts for superior resistance to abrasion and corrosion

- Floating ball design: ball is pressed against the downstream seat under differential pressure to ensure tight shut-off

- Available as on/off or throttling (V-type) for better flow control in erosive applications

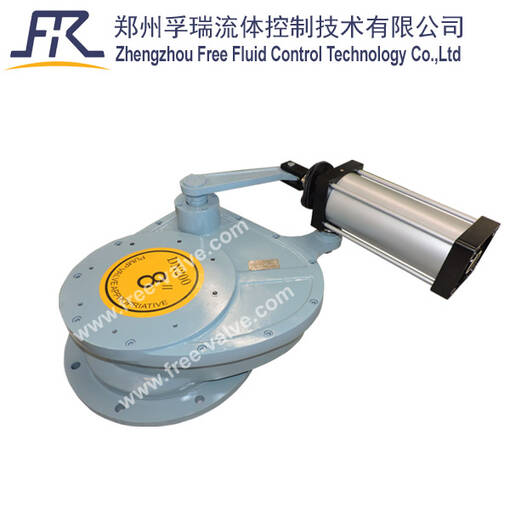

- Multiple actuation options: manual lever or gearbox, pneumatic, electric or hydraulic actuators can be fitted

- Flanged connection (ASME-compatible) for straightforward installation and maintenance

- Pressure and dimensional testing per GB/T13927 / API598 and GB/T12221 / API609 respectively

Technical highlights

- Size range: DN50 – DN200 (NPS 2 – NPS 8)

- Connection type: Flange

- Maximum service temperature: ≤ 200 °C

- Sealing surface: Engineering ceramic

- Operation: Manual, pneumatic or electric actuation available

Applications

Designed for heavy-duty, high-wear environments handling abrasive or corrosive materials, including silicon and alumina powders, dry coal powder, limestone and gypsum slurries, fly ash, mining ores, coal injection, metallurgical dust handling, and FGD systems in thermal power plants. Suitable for chemical, mining, cement, power generation and powder-processing industries.

Options and customization

Actuation, V-type control geometry, and other component materials can be customized to suit plant specifications and service conditions. Standard flange dimensions follow ASME practice; face-to-face and pressure testing comply with common industrial standards to facilitate integration into existing piping systems.