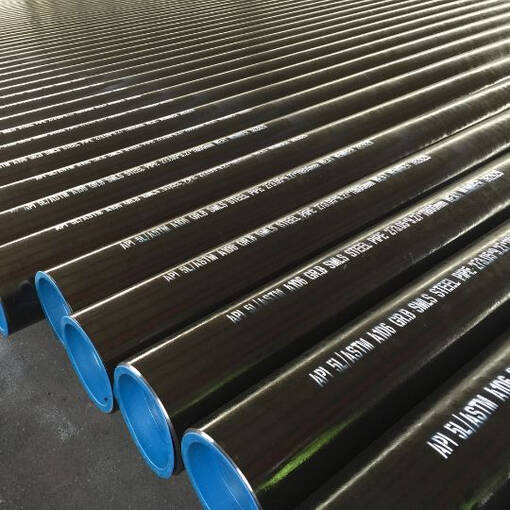

Electric-fusion-welded (EFW) carbon steel pipes manufactured to ASTM A671 for atmospheric and lower-pressure service. Engineered for pressure-containing and structural applications, these welded pipes are supplied in multiple grades, sizes, schedules and end treatments to meet industrial requirements in oil & gas, petrochemical, power generation, boilers, pressure vessels and general engineering.

Key features

- Standard: ASTM A671 (electric-fusion-welded steel pipe with filler metal added)

- Size range: 16" to 100" outside diameter

- Wall thickness / Schedules: 20, 30, 40, Standard (STD), Extra Heavy (XH), 80, 100, 120, 140, 160, XXH and heavier on request

- Available grades (selection): CA55, CB60, CB65, CB70, CC60, CC65, CC70, CD70, CD80, CF65, CF70, CF66, CF71, CG100, CH100, CJ101–CJ113, CK75, CP65, CP75 (full grade list available on request)

- Types: ERW / Electric-Resistance Welded, Welded, Fabricated, Cold Drawn Welded (CDW)

- Forms: round pipes/tubes, square and rectangular sections, coiled tubes, "U" shapes, pan-cake coils, hydraulic tubes

- Lengths: single random, double random, and cut-to-length; standard up to 12 m (custom lengths available)

- End configurations: plain ends, beveled ends, threaded/screwed ends

- End protection: plastic caps fitted for shipment

- Surface finishes & coatings: black paint, anti-corrosion oil, hot-dip galvanised finish, or customer-specified coatings

- Delivery condition: annealed, normalized, normalized & tempered (specify on order)

Testing and certification

Comprehensive inspection and test reports are available, including:

- Chemical composition analysis

- Mechanical properties: tensile strength, yield strength, elongation

- Hardness testing

- Impact tests where specified

- Flaring, flattening and dimensional checks

- Non-destructive testing (NDT) and hydrostatic testing upon request

- Material Test Certificates (MTC) and compliance documentation per ASTM A671

Typical applications

- Oil refineries and pipelines

- Petrochemical plants

- Power generation (thermal and nuclear) systems

- Boilers and pressure vessels

- Steelworks and heavy engineering

- Sugar and process industry equipment

Ordering information

To obtain a quote, please specify required: grade, OD, schedule/wall thickness, length, end type, coating/finish, delivery condition and required quantity. RFQs and technical queries can be submitted through this listing on the marketplace; available customization and inspection options will be confirmed with your order.