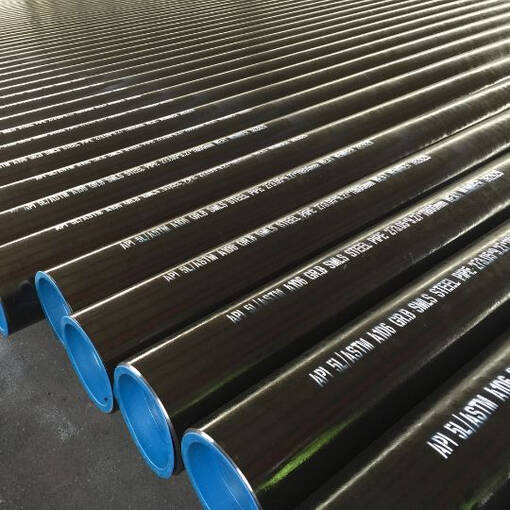

Heavy-wall carbon steel pipe manufactured to ASTM A53 requirements and supplied in Schedule 80 wall thickness. These pipes are produced as low‑carbon (mild) steel and are commonly specified where enhanced wall thickness and pressure capability are required compared with lighter schedules.

Key features

- Standards: Manufactured to ASTM A53 specification (Grades A and B available).

- Construction: Seamless (Type S) — also available in welded forms described under ASTM A53 (Type E — electric‑resistance welded; Type F — furnace‑butt welded).

- Material: Low‑carbon (mild) steel suitable for forming and welding; can be carburized for surface hardening where required.

- Wall thickness: Schedule 80 — heavier wall for higher pressure and greater mechanical strength than Schedule 40.

- Finishes: Supplied plain/black, hot‑dipped galvanized (zinc coated), or prepared for further coating; end finishes and beveling/cutting to length on request.

Typical applications

- Structural members and supports

- Mechanical piping and conduit systems

- Water, steam and low/medium‑pressure pressurized systems (confirm suitability for specific fluids and temperatures against local codes)

- Industrial fabrication, scaffolding and general engineering uses

Supply & services

- Available in a range of diameters and cut lengths; custom lengths and end preparations on request

- Mill test certificates (MTC), dimensional inspection and test reports available upon request

- Supplied packed and protected for export or domestic shipment

Ordering recommendations

When requesting a quotation, please specify: required standard (ASTM A53 Grade A or B), outside diameter, schedule (Schedule 80), length or cut‑to‑length requirement, end finish (plain, beveled, threaded), surface finish (black, galvanized), and any required inspection or certification.

Note: Ensure final selection and installation conform to applicable codes and service conditions (pressure, temperature, fluid type).