High-strength, low-alloy steel tubing manufactured to ASTM A519 for consistent mechanical performance and excellent weldability. AISI 4130 (Cr–Mo) tubing combines good strength, toughness and heat-treatability while retaining relatively low carbon content for improved fusion weldability — making it suitable for structural, aerospace and industrial welded tubing applications.

Key features

- Standard: ASTM A519 (AISI 4130)

- Material: AISI 4130 low-alloy chromium–molybdenum steel

- Mechanical characteristics: heat-treatable, good tensile and yield strength, good elongation and toughness; suitable for welding and secondary fabrication

- Manufacture: available cold-finished or hot-finished

Available sizes and wall thickness

- Outside diameters: 4" to 36" (other sizes on request)

- Wall thicknesses / schedules: Sch 5, 10, 20, 30, 40, 60, 80, 100, 120, 140, 160, XS, XXS, STD (custom schedules on request)

End preparations and coatings

- Ends: plain end, beveled end, threaded; each length supplied with protective plastic end caps

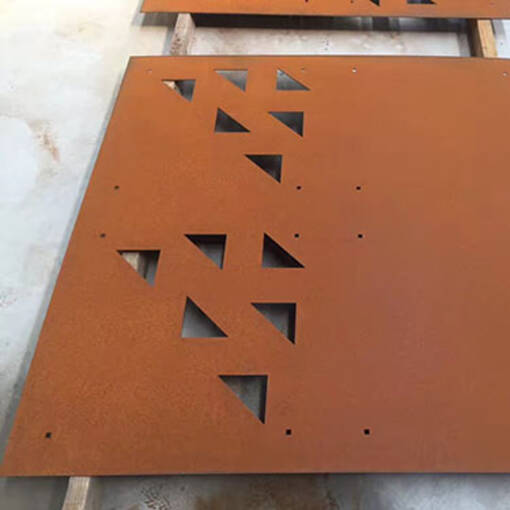

- Coatings / surface finishes: anti-corrosion oil, galvanized finish, black paint, oil-dip, lacquer, passivation, phosphating or customer-specified coatings

Quality assurance and testing

- Supplied with full material test certificate (MTC) per ASTM A519 on request

- Typical inspection and tests: chemical composition analysis, mechanical properties (UTS, yield, elongation), flattening, flaring, bending, hardness, hydrostatic test, nondestructive electric testing, magnetic particle inspection and external dimensional inspection

- Manufacturing and inspection performed to standard industrial tolerances; strict quality control to minimize rejections and support repeat purchasing

Typical applications

- Aerospace and aircraft structural components (e.g., engine mounts)

- Automotive and bearing industry components

- Mechanical and structural tubing

- Hydraulic, petrochemical and pressure systems

Ordering and customization

- Custom lengths, end-prep, coatings and special testing available on request

- Send RFQ with required size, schedule, quantity, coating and inspection requirements to receive a competitive commercial offer and lead-time

If you require a specific certificate set, heat treatment condition, or dimensional tolerance, include those requirements in your RFQ so we can confirm conformance and provide pricing.

Product Details

Harmonized commodity

Brand:

BBN Steel

Country of origin:

China

Industrial sector:

Unit type:

Metric Ton