X10CrAlSi7 (1.4713) is a ferritic, heat‑resistant stainless steel designed for high‑temperature service in non‑aggressive atmospheres (service temperature up to ~800 °C as supplied). The alloy demonstrates good resistance to sulfur compounds and to reducing and carburizing gases, making it suitable for components exposed to hot corrosive environments in energy, automotive and metallurgical applications.

Key features

- Heat resistance to approximately 800 °C in non‑aggressive atmospheres

- Improved resistance to sulfur compounds and reducing/carburizing gases

- Intended for load‑bearing and high‑temperature structural parts

Typical applications

- Parts for steam boilers and soot blowers

- Supports, hubcaps and sliding rails

- Chains, sieves and other high‑temperature components

- Components for automotive, energy and metallurgical equipment

Mechanical properties (as provided)

- Tensile strength (Rm): 420–620 MPa

- Yield strength (Rp0.2): > 220 MPa

- Elongation (A): > 15 %

- Hardness (HB): < 192

- Specific heat capacity (cp): ~450 J·kg⁻¹·K⁻¹

Notes

- The values above are supplier‑stated properties; final properties depend on product form, heat treatment and fabrication processes.

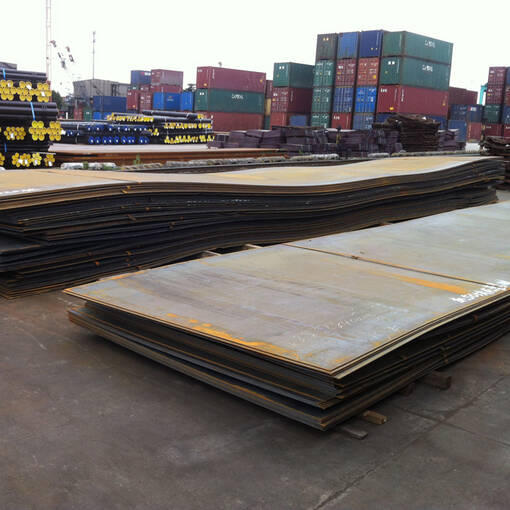

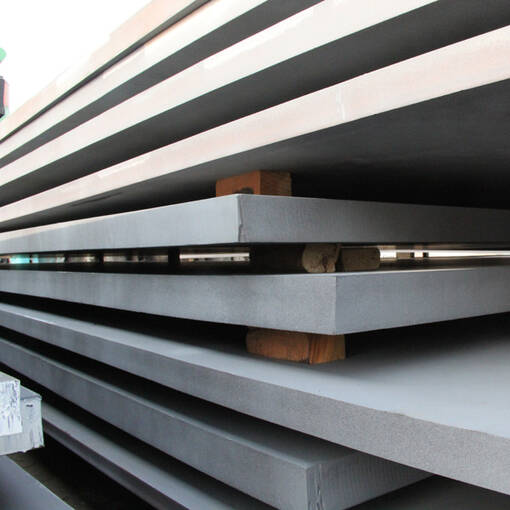

- Chemical composition, available product forms (sheet, strip, bar, tube, forgings) and surface condition are not specified here — please request technical datasheets or supply specifications to confirm suitability for your application.

For procurement: indicate required form, dimensions, heat treatment and quantity so the supplier can provide lead time, certification and testing data.

Product Details

Harmonized commodity

Country of origin:

China

Industrial sector: