A corrosion-resistant, self-priming centrifugal pump with a fluoroplastic-lined wet end and magnetic drive that eliminates shaft seals and associated leakage risk. The fluoroplastic liner protects all wetted components from aggressive media while the metal pump casing provides structural support for piping and installation.

Key features

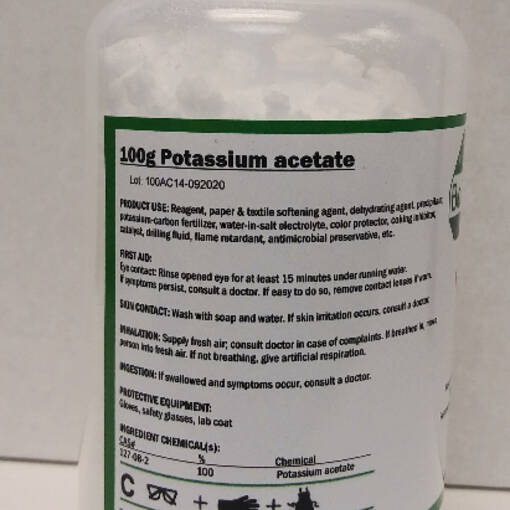

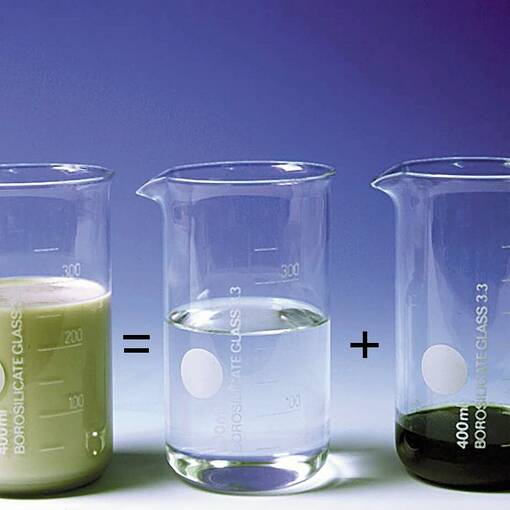

- Fluoroplastic-lined flow path for high chemical resistance (acids, alkalis, salts and many organic solvents)

- Magnetic coupling drive — seal-less construction prevents drips and fugitive emissions, improving plant safety and reducing maintenance

- Self-priming capability with typical suction lift of 2–4 m; can achieve up to 4 m self-priming when the pump cavity is initially filled

- Robust metal pump body able to bear pipeline weight and mounting loads

- Efficient hydraulic design for energy savings and continuous operation

Performance range

- Flow: 3.6–60 m3/h

- Head: 25–48 m

- Motor power: 2.2–18.5 kW

- Medium temperature: -20 to 100 °C

- Typical media: moderate concentrations of acids, alkalis, salts, and many organic solvents

Typical applications

- Chemical processing and reagent transfer

- Electroplating, pickling and surface treatment lines

- Pesticide and specialty chemical manufacturing

- Non-ferrous metal smelting and rare-earth separation

- Paper and foil production, electronics manufacturing

- Acid/alkali wastewater collection and discharge

Why choose this design

The combination of a fluoroplastic-lined wet end and a magnetic drive delivers long service life in corrosive environments while eliminating mechanical seals and the leakage they cause. The pump’s metal casing supports installation in industrial piping systems, and its self-priming capability simplifies startup and installation where suction lift is required. Specify by model or performance point to match site requirements and materials compatibility.