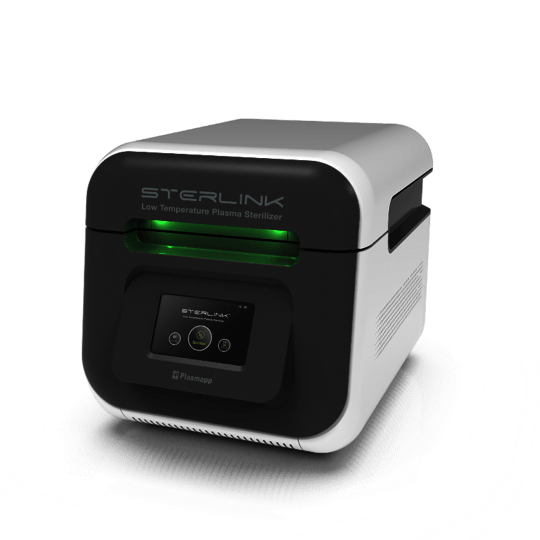

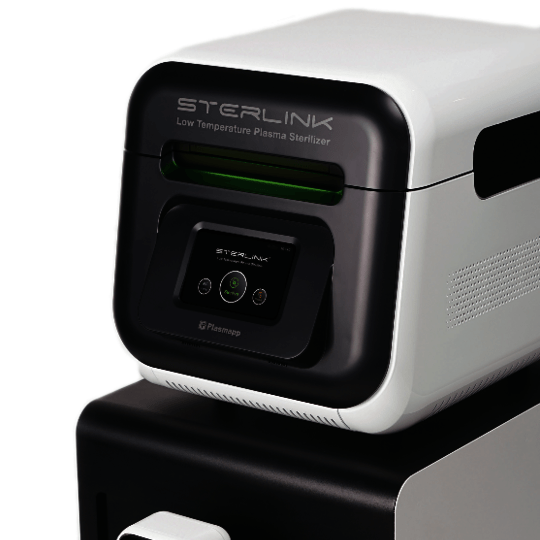

Low-temperature plasma sterilization system engineered for rapid turnaround of heat-sensitive medical, surgical and laboratory instruments — including instruments with lumens. The system uses the world’s first direct-injection pouch-type patented sterilization technology and is validated to SAL 10^-6 to ensure reliable microbial inactivation for clinical and laboratory workflows.

Key benefits

- Rapid cycle times to increase instrument availability and throughput

- Validated SAL 10^-6 for consistent sterilization of instruments, including lumened devices

- Patented direct-injection pouch technology designed for efficient sterilant delivery into wrapped instruments

- Compact footprint suitable for point-of-care locations, clinics, dental practices, outpatient surgical centers and laboratories

Technical specifications

- Available chamber capacities: 1 L (0.3 gal), 4 L (1.1 gal), 14 L (3.7 gal)

- Typical sterilization cycle times (depend on load and program): ~7 min, ~14 min, ~36 min

- External dimensions: Width 433 mm (17 in) × Height 437 mm (17.2 in) × Depth 614 mm (24 in)

- Intended use: Medical, surgical and laboratory sterilization of heat- and moisture-sensitive instruments

Applications

Suitable for sterilizing delicate instruments such as endoscopes’ accessories, ophthalmic and dental tools, microsurgical instruments and other devices that cannot tolerate high-temperature steam sterilization. The combination of quick cycles and a small footprint makes it useful where rapid instrument turnaround and space savings are priorities.

Ordering considerations

Select the chamber capacity and cycle program that match your typical instrument sets and throughput needs. Confirm compatibility with the pouches and consumables required by the direct-injection pouch system.