Hot-rolled fine-grain structural steel produced to the S420M grade, designed for heavy welded constructions requiring a high minimum yield and good low-temperature toughness. S420M delivers a guaranteed minimum yield strength of 420 MPa (for nominal thicknesses ≤ 16 mm) and is supplied in an "M" delivery condition that specifies minimum impact energy values at temperatures down to -20°C.

Key features

- Minimum specified yield strength: 420 MPa (≤ 16 mm nominal thickness).

- Delivery condition M: impact-tested to specified minima at temperatures not lower than -20°C.

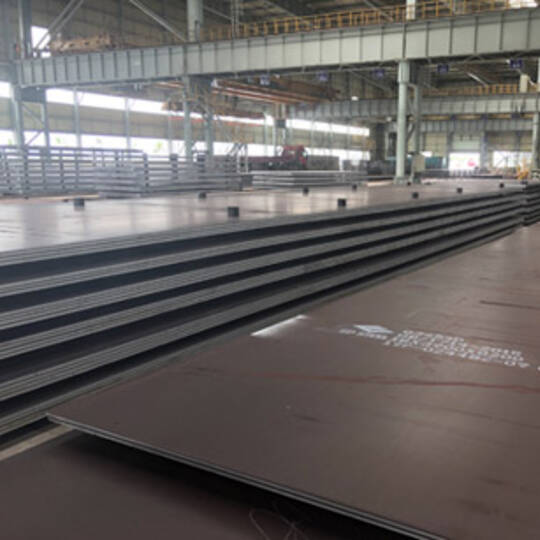

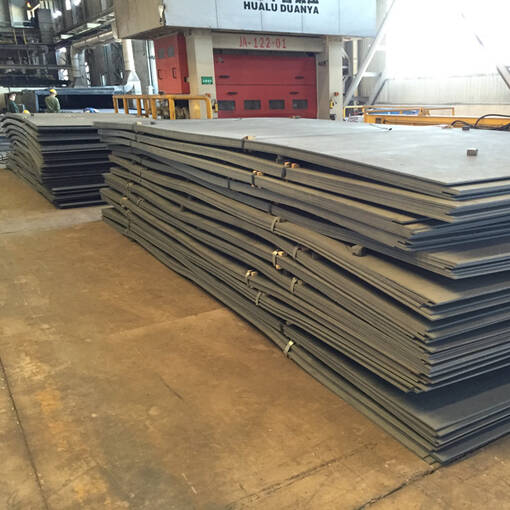

- Available in flat product thicknesses up to 120 mm and long product thicknesses up to 150 mm.

- Weldable fine-grain structural steel suitable for heavy welded components.

Mechanical and performance notes

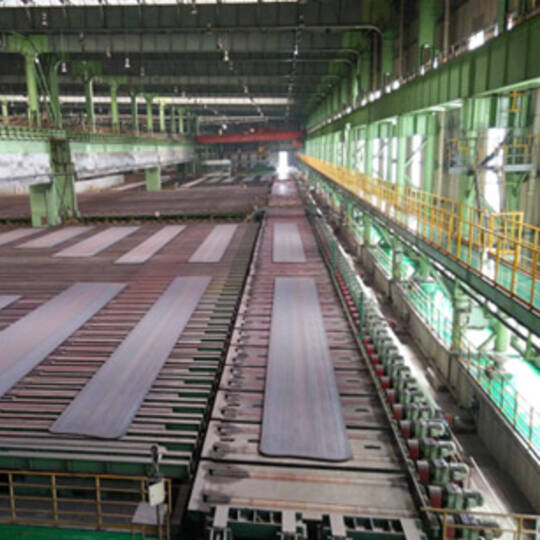

- Thermo-mechanical rolling gives improved strength and toughness; however, subsequent heating above ~580°C will reduce strength and should be avoided for thermo-mechanically rolled material.

- By arrangement, a notch impact energy of 27 J (longitudinal specimen) at –50°C can be warranted for applications requiring lower temperature performance.

Chemical / fabrication guidance

- Typical carbon equivalent (by arrangement):

- Nominal size < 16 mm: 0.43%

- Nominal size 16–40 mm: 0.45%

- Good weldability for common structural welding processes; specific welding procedure approvals should be used for critical fabrications.

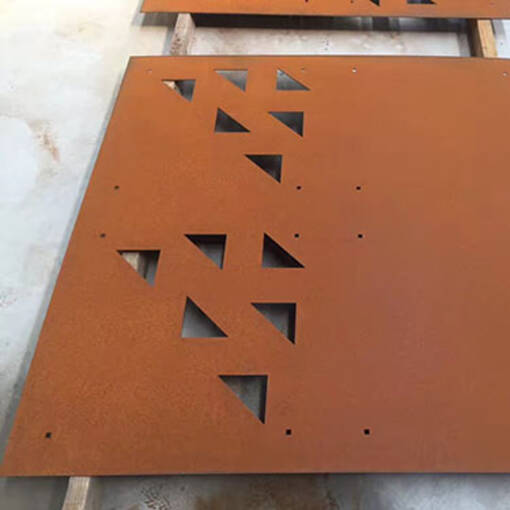

- Cold forming (bending, folding, flanging) may be possible but suitability must be verified for the specific thickness and temper. Thermo-mechanically rolled grades are generally unsuitable for warm forming.

Typical applications

- Heavily loaded welded structures: bridges, flood gates, storage tanks, water-supply tanks and other structural components used at ambient or low temperatures.

Quality and ordering

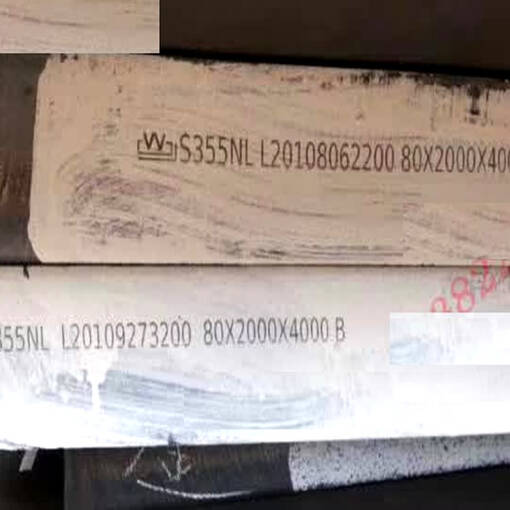

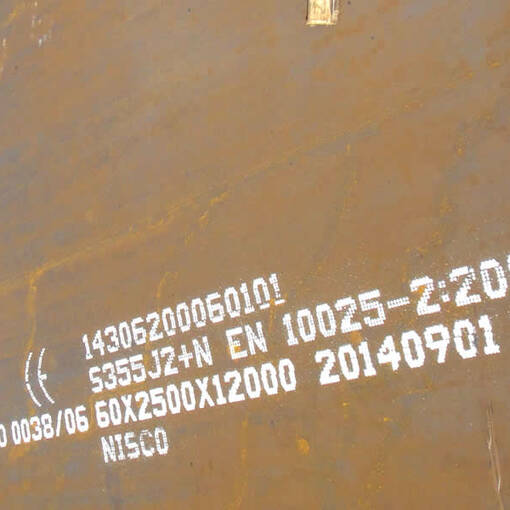

- Supplied to recognized EN structural-steel specifications (see applicable EN 10025 series for S-grade requirements).

- Available for custom plate sizing, cut-to-length, and commercial processing — please provide thickness, plate size, required impact temperature, and any certification/inspection requirements when requesting a quote.

For quotations or technical clarifications, provide application details, required dimensions, and any testing/certification needs to obtain an accurate RFQ.

Product Details

Harmonized commodity

Brand:

BBN Steel

Country of origin:

China

Industrial sector:

Unit type:

Metric Ton