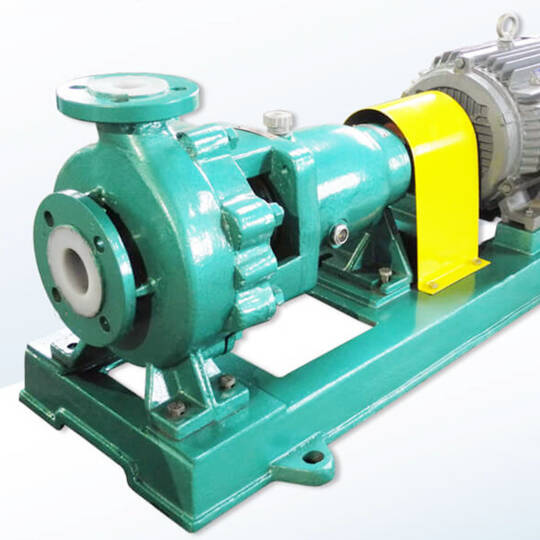

A heavy-duty, single-stage centrifugal transfer pump engineered for continuous handling of highly corrosive, high-temperature liquids. The cantilever, single-suction design combines a corrosion-resistant fluoropolymer lining with metal structural inserts to deliver chemical compatibility, mechanical strength and reliable operation up to 150 °C.

Key features

- Construction: single-stage, single-suction, cantilever centrifugal pump for inline chemical transfer and circulation.

- Lining and wetted parts: corrosion- and wear-resistant fluoroplastic (fusible polytetrafluoroethylene PFA or fluorine ceramic alloy) applied to the pump body; impeller and pump cover use metal inserts encapsulated in PFA/fluorine ceramic alloy for improved structural integrity.

- Mechanical seal: built-in water-cooled double-end mechanical seal for enhanced sealing life in aggressive media and high-temperature service.

- Standards: designed to ISO 2858 dimensional and performance principles for centrifugal pumps.

Performance & operating limits

- Continuous operation at temperatures up to 150 °C (service conditions depend on exact fluid properties and installation).

- Suitable for liquids with up to 15% solid content and for saturated or easily crystallized solutions.

Typical applications

- Transfer and circulation of strong acids, alkalis and other highly corrosive chemicals.

- Saturated electrolytes in non-ferrous metal processing and electrolysis lines.

- Acid pickling and acid regeneration systems in steel processing.

- Flue-gas desulfurization (FGD), dust removal and other environmental/chemical treatment processes.

Benefits for B2B installations

- High chemical resistance from fluoropolymer lining minimizes corrosion-related downtime and extends asset life.

- Metal core inserts under the fluoropolymer lining provide mechanical strength for pressurized systems while maintaining chemical compatibility.

- Water-cooled double mechanical seal reduces thermal and chemical stress on sealing faces for longer seal life in aggressive, high-temperature services.

- Cantilever design reduces external sealing points and simplifies maintenance and inspection compared with some shaft-sealed designs.

Notes for specification and procurement

- Verify compatibility of PFA/fluorine ceramic alloy lining with specific process fluids (concentration, temperature and any abrasive particulates).

- Confirm required hydraulic size and motor/driving arrangement for the model and system head/flow requirements.

- Provide process parameters (fluid, temperature, solid content, required flow and head) to receive an exact selection or quote.

Product Details

Harmonized commodity

Brand:

kenshine-pump

Country of origin:

China

Industrial sector:

SKU:

SET

GTIN/EAN:

841370

MPN:

IHF-NS

Model:

IHF65-50-160-NS

Unit type:

Set

Minimum order (MOQ):

1