High-strength, cold-forming structural steel produced to the EN 10149 specification. S355NC is a normalized, non-alloy (low-alloy) structural steel grade designed for applications that require good weldability and excellent formability in both longitudinal and transverse directions. The material offers very good bending, flanging, cold-bordering and folding behaviour when processed using state-of-the-art forming methods.

Key features

- Conforms to EN 10149 series requirements for high-strength steels for cold forming (normalized condition). The "N" indicates a normalized heat treatment and the "C" denotes controlled rolling.

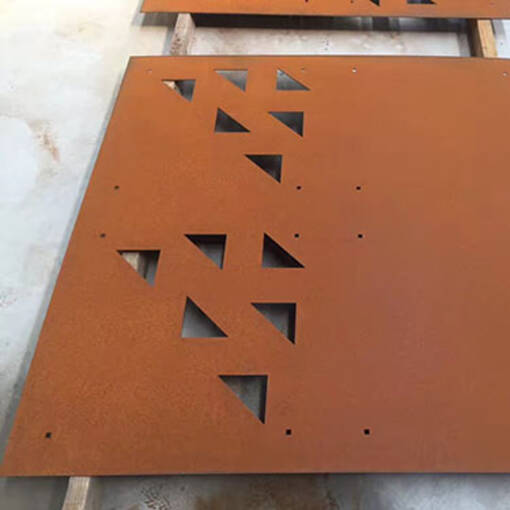

- Excellent cold-forming performance: suitable for bending, flanging, hemming and other forming operations with conservative minimum bend radii to be observed for the chosen thickness and temper.

- Good weldability and machinability when processed according to recommended procedures.

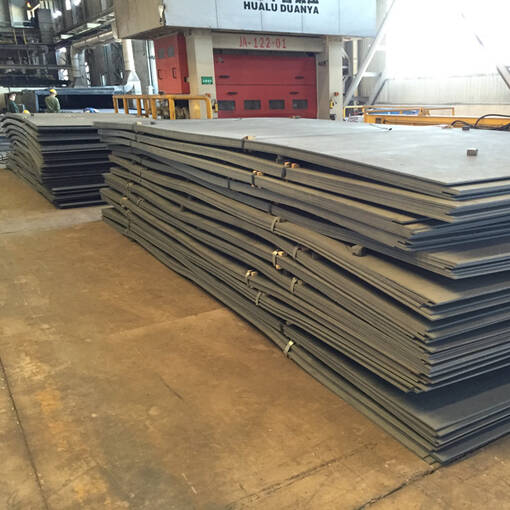

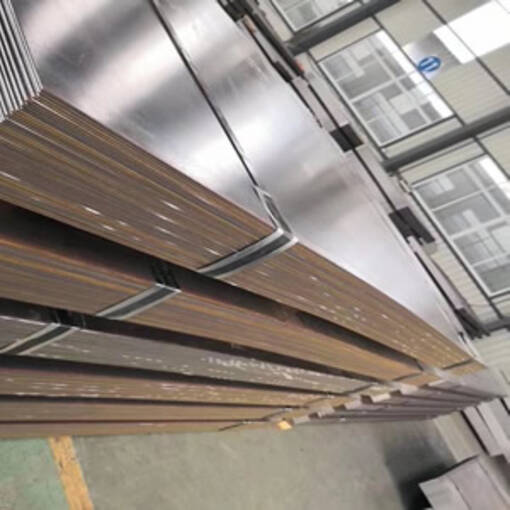

- Typical supply forms: plates, sheets and coils (specify thickness, width and length when requesting a quote).

Typical applications

- Structural components and welded assemblies

- Heavy machinery and equipment frames

- Automotive structural parts and chassis components

- Cold-formed sections, profiles and fabricated parts

Ordering / RFQ guidance (please include these items in enquiries)

- Product standard and grade: EN 10149 S355NC

- Form: plate, sheet or coil

- Dimensions: thickness, width and length (or coil inner/outer diameters and weight)

- Surface finish and edge preparation

- Required quantity and delivery schedule

- Required certifications (e.g., EN 10204 2.2 / 3.1 mill test certificates)

- Intended forming/welding processes or specific application constraints (to confirm appropriate temper and bend radii)

Quality & process notes

- Ensure design and processing methods are appropriate for cold-forming high-strength steel. Minimum bending radii depend on thickness, temper and tooling; these must be observed to avoid cracking.

- If paint, galvanizing or additional coatings are required, specify pre-treatment and coating requirements at order stage.

Provide detailed specifications and application intent with your RFQ so the supplier can confirm suitability, recommended forming parameters and provide compliant certification and traceability.

Product Details

Harmonized commodity

Country of origin:

China

Industrial sector:

Unit type:

Metric Ton