High-strength molybdenum-alloy plate engineered for welded boilers and pressure-vessel applications. ASTM A204 Grade B is an as-fabricated (no temper or post-treatment required) alloy-steel plate with enhanced elevated-temperature strength and weldability compared to plain carbon steels.

Key specifications

- Standard: ASTM A204 (molybdenum alloy steel plates)

- Grade: A204 Grade B

- Typical mechanical properties (at 20 °C): tensile strength Rm ≈ 620 MPa; yield strength YS ≈ 275 MPa

- Condition: supplied in the as-fabricated state

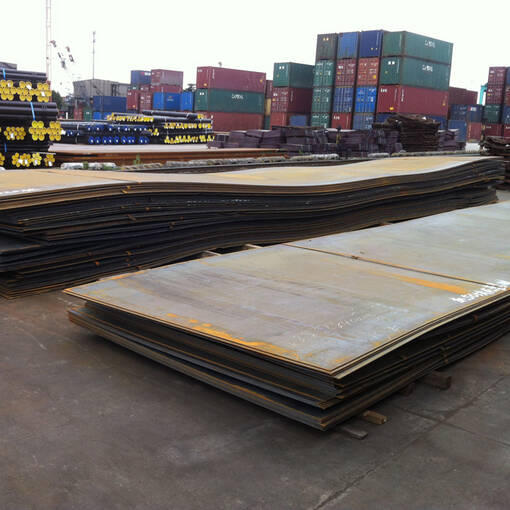

Available product forms and dimensions

- Plate thickness: 3 – 150 mm (note: coils available for thickness ≤ 25 mm)

- Width: 1,220 – 4,200 mm

- Length: 5,000 – 18,000 mm

- Supply forms: cut-to-size plate; full coils (where coil thickness ≤ 25 mm)

Chemical and metallurgical notes

- Alloying: molybdenum-bearing steel (ASTM A204 specifies limits for C, Si, Mn, P, S and Mo)

- Manufactured and tested to meet the chemical composition and tensile requirements called out in ASTM A204

Typical uses

- Welded boilers and superheater tubes

- Pressure vessels and high-temperature pressure-retaining components

- Power generation, petrochemical and industrial boilers where improved creep and high-temperature strength are required

Fabrication and testing

- Good weldability for welded boiler and pressure-vessel construction (follow applicable welding procedures and pre/post-heat recommendations for the completed assembly)

- Tension tests and chemical analysis are performed to verify compliance with ASTM A204 requirements

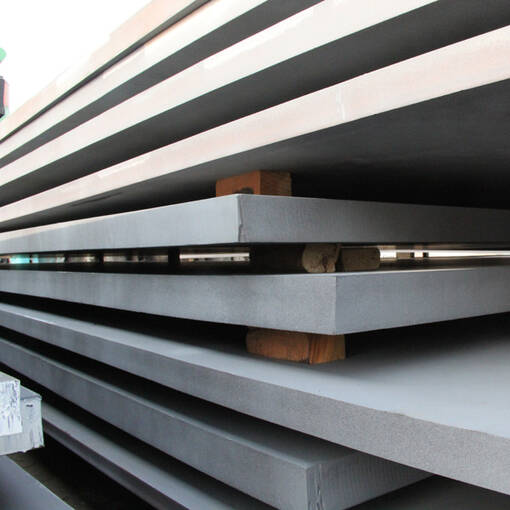

- Supplied in heavy plate or coil forms suitable for sawing, flame cutting, machining and forming operations (observe recommended practices for alloy steels)

Ordering information

Specify grade (A204 Grade B), required dimensions (thickness × width × length), quantity, and any certification or inspection requirements (e.g., mill test certificate, third-party inspection) when requesting a quote. For coil orders, confirm maximum coil thickness and required cutting or slitting services.

If you need detailed mill test documentation, certification, or custom processing (heat treatment, flattening, edge trimming), include these requirements with your enquiry so suppliers can quote lead time and cost accurately.