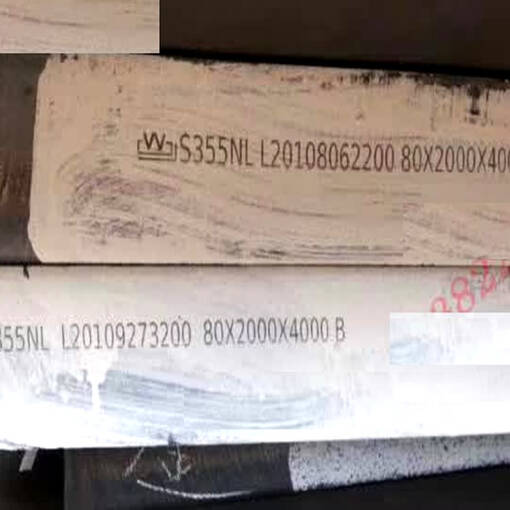

High-strength normalized structural plate manufactured to EN 10025-3 for applications that require enhanced notch toughness at low temperature. S355NL is a fine-grain, low-alloy structural steel produced by a normalizing heat treatment (heating above the critical temperature and air cooling) to produce a uniform austenitic microstructure and improved mechanical properties and weldability.

Key features

- Standards: EN 10025-3 (S355NL)

- Condition: Normalized (fine grain)

- Low-temperature toughness: Manufactured and tested to meet the NL requirements for impact testing at low temperatures (typically specified down to -50 °C in project specifications)

- Mechanical performance: Engineered for high yield and tensile strength suitable for heavy structural applications; supplied with factory test reports and mechanical test records on request

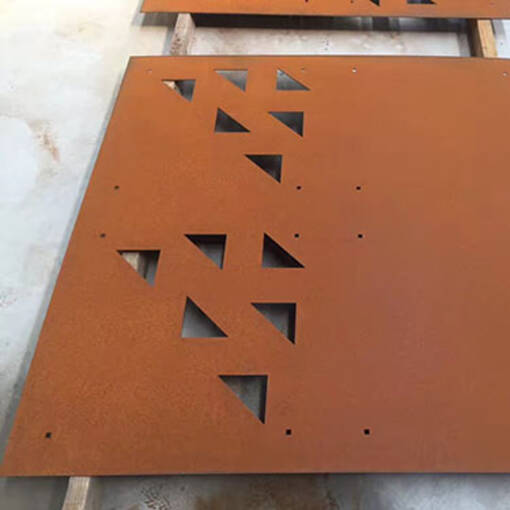

- Fabrication: Good weldability and formability for common joining methods; suitable for submerged-arc welding, MIG/MAG and other structural welding processes when proper filler materials and procedures are used

- Quality & testing: Available with visual inspection, ultrasonic testing (UT), radiographic testing (RT), and mechanical testing (tensile, impact) per customer or project requirements

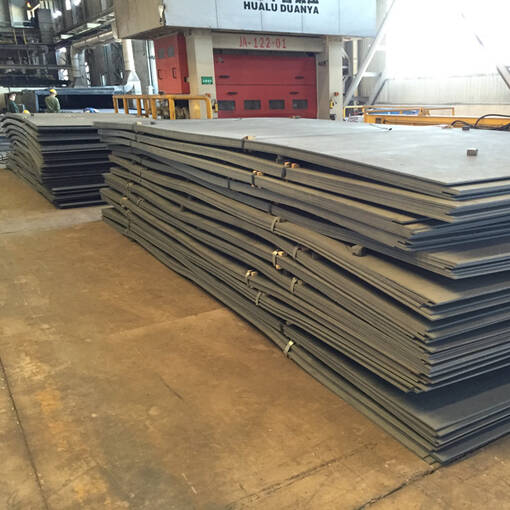

Available dimensions (typical supply range)

- Thickness: 3 – 150 mm

- Width: 1,220 – 4,200 mm

- Length: 5,000 – 18,000 mm

Typical applications

- Heavy steel fabrication: beams, girders, columns

- Bridges and civil infrastructure

- Rail and rolling-stock components

- Offshore and marine structures where low-temperature toughness is required

- Large welded structures and pressure-bearing components

Supply & documentation

Plates can be supplied cut-to-length, edge-prepared or as full-size plates. Certified material test reports (MTRs) and mill certificates to EN 10204 are available on request. For quotes, specific dimensions, tolerances, surface finish or welding/fabrication requirements, provide an RFQ with required delivery terms and certification needs.