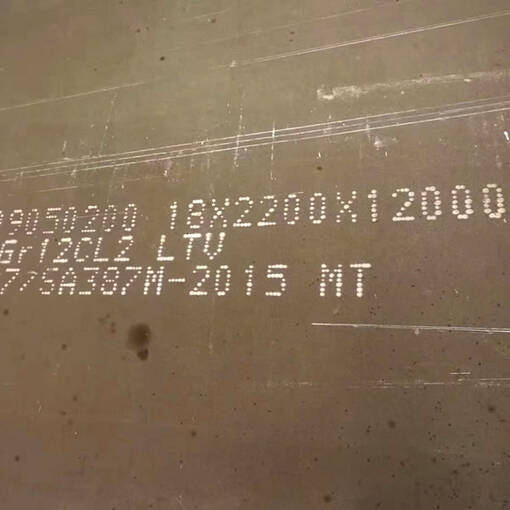

Chromium–molybdenum alloy plate produced to the ASTM A387 Grade 12 Class 1 specification for welded boilers and pressure vessels operating at elevated temperatures. These alloy steel plates are selected where higher strength, improved creep resistance and reliable performance under heat are required compared with ordinary carbon steels.

Key features

- Conforms to ASTM A387 Grade 12 Class 1 (Chromium–Molybdenum alloy steel) for pressure-vessel and boiler applications

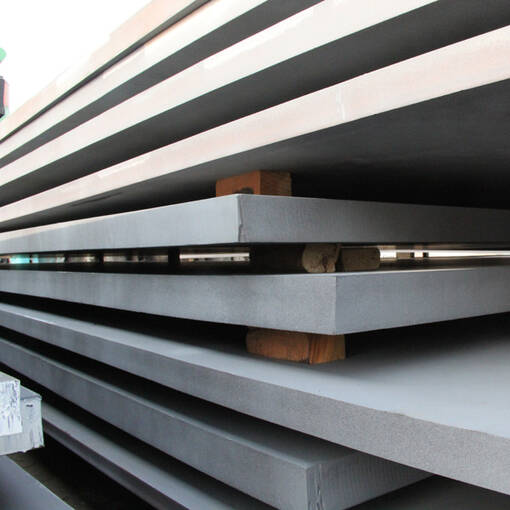

- Thickness range: 3–150 mm

- Width range: 1,220–4,200 mm

- Length range: 5,000–18,000 mm

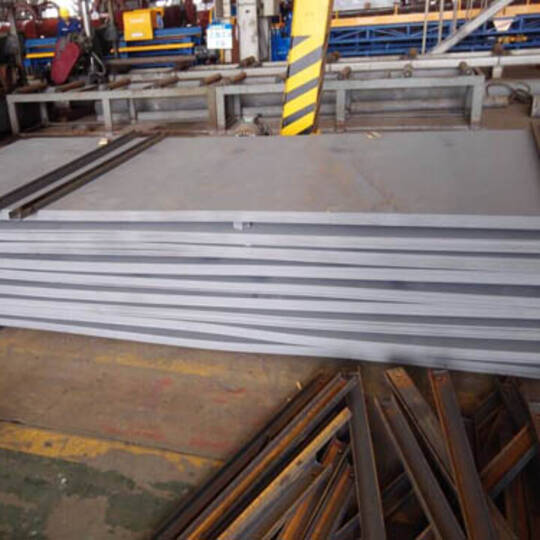

- Supplied in flat plates suitable for welding, machining and further fabrication

Available inspections and test services

- Chemical composition analysis and certified mill test report (MTR)

- Mechanical testing: tensile test, high-temperature tension test

- Impact and fracture testing: Charpy V-Notch impact test, drop-weight test (as required)

- Non-destructive testing: ultrasonic examination (UT), magnetic particle inspection (MPI)

- Dimensional and visual inspection

Supply and processing options

- Cut-to-size and sawing to customer specified dimensions

- Machining and edge preparation for weldability

- Surface condition and packaging tailored for export or storage

- Quality management and traceability documentation available on request

Typical applications

- Welded boilers and heat exchangers

- Pressure vessels and steam-generating equipment

- High-temperature piping and welded fabrications in power-generation and petrochemical plants

Notes

Mechanical properties and allowable stresses can vary with plate thickness and heat treatment. Specify required tests, certification level and dimensional tolerances when requesting a quotation so materials can be supplied to your project requirements.

Product Details

Harmonized commodity

Country of origin:

China

Industrial sector: