ASTM A299 Grade B plates are manganese-silicon carbon steel plates engineered for welded boilers, pressure vessels and other high-pressure, high-temperature applications. Supplied killed with a fine austenitic grain size, these plates are produced and tested to meet the mechanical and chemical requirements of ASTM A299 for Grade B material.

Key features

- Material: ASTM A299 Grade B (manganese-silicon carbon steel), killed steel with fine austenitic grain size

- Typical applications: welded boilers, pressure vessels, heat exchangers, high-pressure tanks and related pressure-retaining equipment

- Mechanical note: specified minimum yield strength is reduced for plate thicknesses over 1 inch (25 mm) as per the ASTM specification

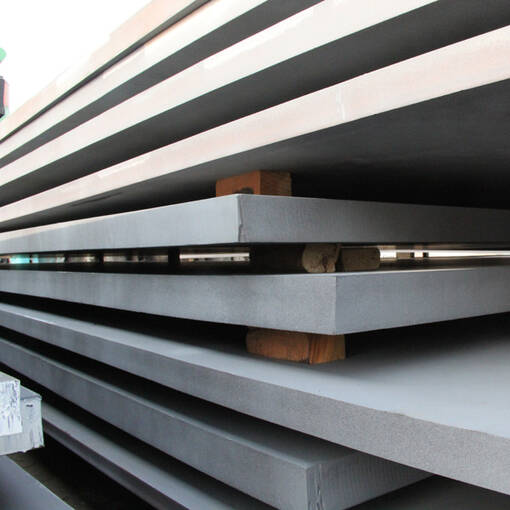

Available dimensions (standard range)

- Thickness: 3 – 150 mm

- Width: 1,220 – 4,200 mm

- Length: 5,000 – 18,000 mm

Quality assurance & testing (optional / on request)

- Chemical composition analysis

- Tensile (room-temperature and high-temperature) tests

- Charpy V-Notch impact testing

- Drop weight testing

- Ultrasonic examination (UT)

- Magnetic particle inspection (MPI)

- Dimensional and visual inspection

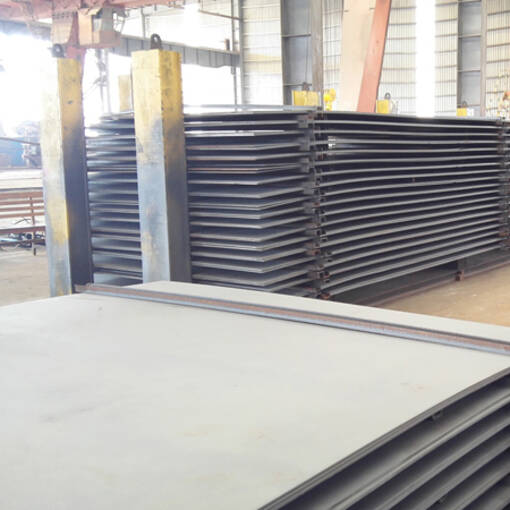

Processing & customization

- Precision cutting to customer-specified sizes

- Edge preparation, beveling and drilling

- Machining and surface treatments available per order

- Supplied in condition compliant with ASTM A299; additional processing and certification packages available on request

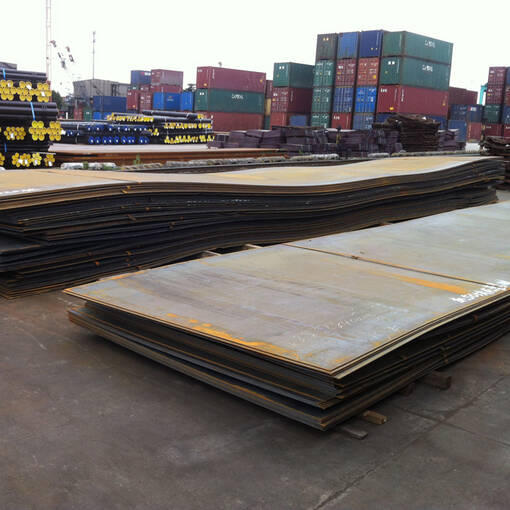

Commercial & packing details

- Stock and cut-to-order options for fast lead times

- Quality management systems in place (supplier ISO accreditation reported)

- Packing suitable for export: protected, stacked and banded to prevent damage in transit

If you require a certified quotation, detailed mill test reports, or specific test certificates (e.g., full chemical and mechanical certificates, NDE reports), provide application details, required dimensions, and any special testing or certification needs so we can propose the appropriate supply and inspection options.