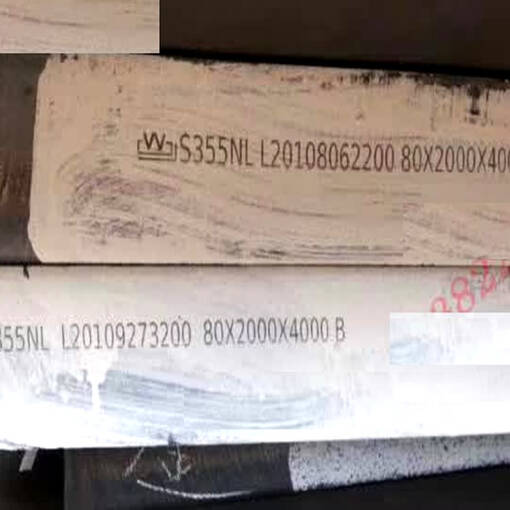

High-strength, fine-grain structural steel plate supplied to EN 10025-4 for welded constructions requiring good low-temperature toughness and high yield strength. S355M is a thermomechanically-treated structural steel grade with a minimum specified yield strength of 355 MPa (for thicknesses ≤16 mm) and an “M” delivery condition that requires specified impact energy values at temperatures not lower than –20 °C.

Key features

- Conforms to EN 10025-4 (fine-grain structural steels)

- Thermo-Mechanical Control Process (TMCP) delivery for improved toughness and controlled grain size

- Minimum specified yield strength: 355 MPa (for thickness ≤ 16 mm)

- Impact-tested in the ‘M’ delivery condition (tested at temperatures down to –20 °C)

- Good weldability and suitability for heavy welded structures

Typical applications

- Bridges and bridge components

- Flood gates and hydraulic structures

- Storage tanks and pressure-retaining welded assemblies

- Water supply tanks and civil and structural engineering fabrications

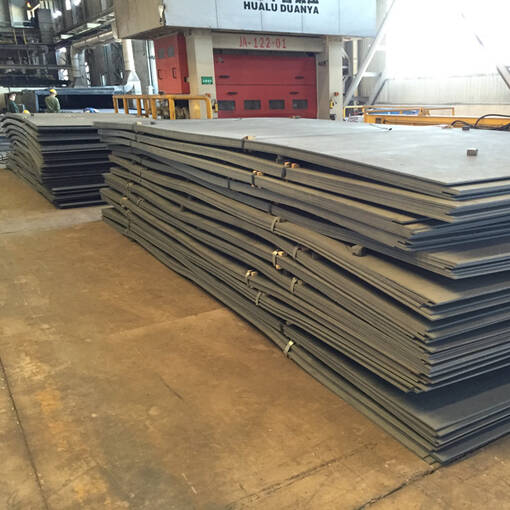

Available dimensions & supply condition

- Thickness: 5 mm – 150 mm (flat products typically available to ≤120 mm; long products up to ≤150 mm)

- Width: 1,500 mm – 3,550 mm

- Length: 3,000 mm – 18,000 mm

- Supply condition: thermomechanically rolled (TMCP), mechanically tested and delivered as plates or flat products

Quality & testing (typical for EN 10025-4 deliveries)

- Chemical analysis to EN 10025 requirements

- Tensile testing (yield and tensile strength)

- Charpy V-notch impact testing at the specified temperature for the ‘M’ delivery condition

- Dimensional checks and visual inspection

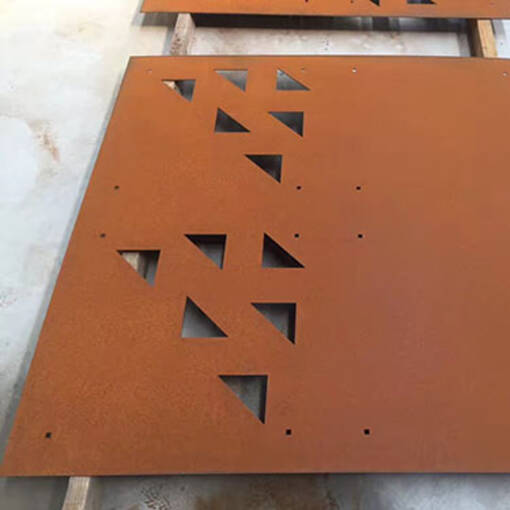

Processing and fabrication notes

- Designed for standard welding procedures used on structural steels; preheating and post-weld heat treatment depend on thickness, joint design and welding consumables

- Can be flame-cut, machined and formed with common fabrication equipment; follow standard recommendations for machining and cutting to maintain mechanical properties

- Surface treatment (paint, primer, galvanizing) may be required for corrosion protection depending on service environment

If you require mill test certificates (MTCs), specific impact temperatures, plate cutting services, or custom lengths/widths, provide your RFQ with required standards and quantities so we can confirm availability, lead time and testing scope.