A family of vertical fiberglass submersible pumps designed for corrosive liquid handling in industrial storage tanks. Available in two configurations: WSY (vertical fiberglass vortex pump) and FSY (vertical fiberglass submersible centrifugal pump). Both types are intended for continuous immersion and are suitable where lightweight, corrosion‑resistant construction is required.

Key features:

- Construction: All wetted components are non‑metallic, made from phenolic fiberglass composites (polyvinyl butyral modified phenolic glass fiber and high‑temperature molded phenolic). Connecting tubes and fluid pipes use rolled semi‑dry process phenolic fiberglass; impeller shaft sleeve assemblies and liquid‑side binders use phenolic materials to ensure chemical resistance and structural integrity.

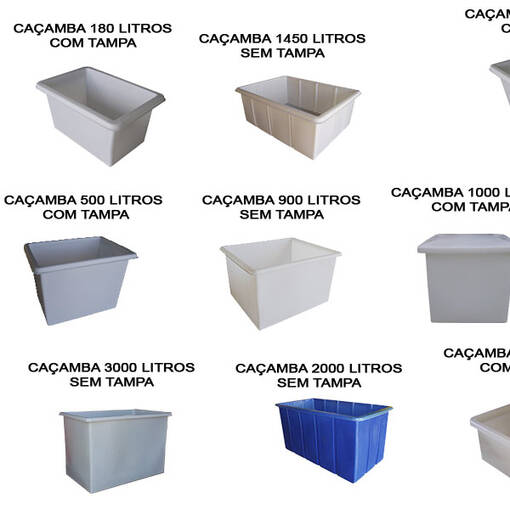

- Pumping depth: Designed fluid depth options from 800 mm to 3000 mm to fit a range of tank depths.

- Installation/startup: When the liquid level is above the pump body the unit can start without pre‑filling. The flat cover plate includes leakage/relief holes to avoid unwanted liquid escape from the storage tank.

- Drive and rotation: Direct motor drive via a claw elastic coupling. Pump rotates clockwise when viewed from the motor end.

- Performance limits and media: Intended for clean corrosive liquids (no suspended solids), non‑crystallizing fluids, with maximum liquid temperature up to 100 °C. Suitable for many oxidizing acids and other corrosive media (examples: hydrochloric acid, dilute sulfuric acid, formic acid, acetic acid, butyric acid).

- Advantages: Lightweight, high strength, non‑deforming, temperature resistant and highly corrosion resistant. In many applications the fiberglass construction can substitute for expensive corrosion alloys such as molybdenum‑bearing stainless steels or titanium alloys.

Typical applications:

Chemical processing, petrochemical, refining, dye and pigment manufacture, pesticides, pharmaceuticals, rare earth processing, fertilizer plants and other industries where aggressive, non‑abrasive corrosive liquids must be contained and transferred safely.

Notes for specification and ordering:

- Choose type (WSY vortex or FSY centrifugal) according to required flow pattern and solids handling tolerance (vortex pumps tolerate some entrained gas; centrifugal units provide standard hydraulic performance).

- Confirm required immersion depth (800–3000 mm options), motor power, impeller size and materials compatibility with the specific chemical being handled.

Contact your procurement team with model reference and operating conditions (fluid type, temperature, tank depth, required flow/pressure) to obtain performance curves and a custom quote.