High-temperature, water-free centrifugal hot oil/thermal oil circulation pump engineered for continuous circulation of weakly corrosive, particle-free heat transfer fluids at service temperatures up to 350°C.

Key features

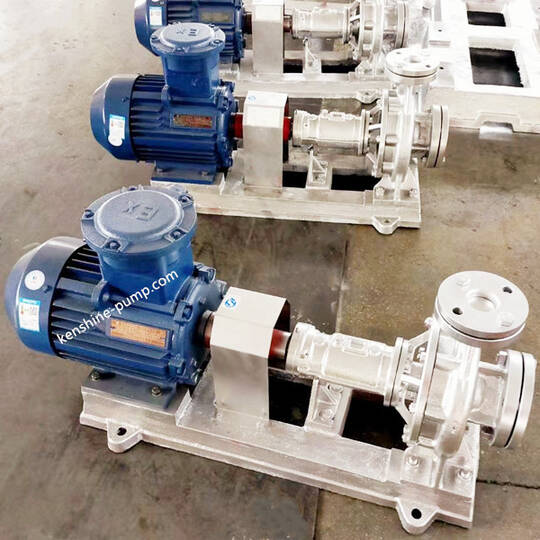

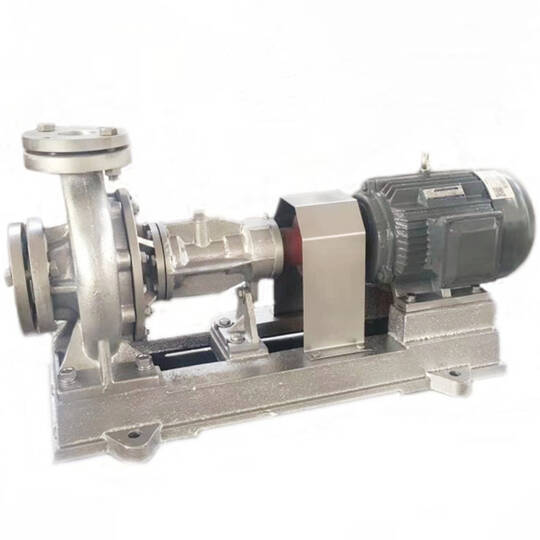

- Single-stage, single-suction cantilever (foot-supported) design with axial suction and vertically upward central outlet; pump and motor are mounted together on a baseplate for compact, aligned installation.

- Robust double-end ball bearing support: front bearing lubricated with oil, rear bearing lubricated with grease. A central guide pipe allows visual inspection of seal condition and recovery of heat transfer oil.

- Natural (air) heat dissipation — replaces traditional water-cooling to simplify structure, reduce footprint and lower operating and maintenance costs.

- Hybrid sealing system: combination of packing seal and mechanical seal. Packing material is specified for thermal adaptability; the mechanical seal uses cemented carbide components for improved high-temperature performance.

- Advanced lip seal using third‑generation PTFE for superior sealing durability and heat resistance (reported significantly higher performance versus conventional rubber lip seals).

Model breakdown (example: WRY 100-65-230)

- WRY: water-free (no water cooling) hot oil pump

- 100: inlet diameter 100 mm

- 65: outlet diameter 65 mm

- 230: impeller nominal diameter 230 mm

Typical applications

Used widely in industrial hot oil circulation and heat-transfer systems across sectors including petroleum, rubber, resin, textile, printing, building materials, road construction and general machinery — suitable for circulating thermal oils and other weakly corrosive, high-temperature, particle-free liquids.

Ordering and specification checklist (provide these when requesting quotes)

- Model number and required flow / head (Q / H)

- Maximum fluid temperature and fluid properties (viscosity, density, corrosiveness)

- Inlet and outlet flange sizes and orientations

- Required mechanical seal / packing materials or special seal arrangements

- Motor coupling and power / speed requirements

- Any special material or surface requirements for wetted parts

Benefits

Compact, serviceable design optimized for high-temperature heat transfer fluids; lower operating cost and maintenance complexity compared with water-cooled alternatives; improved sealing performance for reliable long-term operation in thermal oil systems.