-

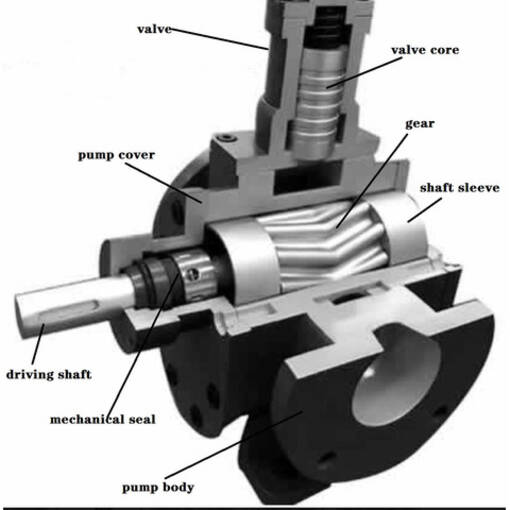

Three-stage (positioning or stages) volumetric MAPSA pumps designed for transferring and dosing fluids through positive displacement. Ideal for industrial processes requiring constant flow rates and precise volume control per cycle.

-

Main features and advantages:

- Positive displacement: stable flow rate independent of pressure within the operating range.

- High precision for dosing and batch processes.

- Good performance with high viscosity fluids and suspended solids (depending on design and materials).

- Robust construction designed for industrial use and easy maintenance.

- Compatibility with various driving sources (electric, gear motor, hydraulic motor) and ease of integration into existing lines.

-

Typical applications:

- Chemical and petrochemical plants

- Dosing of additives and reagents

- Water and wastewater treatment

- Food and pharmaceutical industries (depending on materials and certifications)

- Hydraulic and lubrication systems

-

Technical information facilitating buyers for accurate quotations:

- Required flow rate (L/min or m3/h)

- Maximum working pressure (bar)

- Fluid temperature range

- Fluid viscosity (cP or mPa·s) and presence of solids

- Preferred materials (stainless steel, cast iron, alloys, coatings)

- Type and diameter of connection (BSP/NPT thread, flange, etc.)

- Type of seal (mechanical, packing) and sealing requirements

- Electrical supply and service speed (rpm)

- Regulatory requirements (ATEX, food certifications, etc.)

-

Available services and support (check availability):

- Supply of spare parts and maintenance kits

- Field repair and commissioning

- Material or configuration adaptations for aggressive fluids

To request a quotation or receive a technical sheet, specify the operating conditions and the requirements listed above. With these data, we can confirm the model, dimensions, performance, and delivery times.

Product Details

Country of origin:

Spain

Industrial sector: