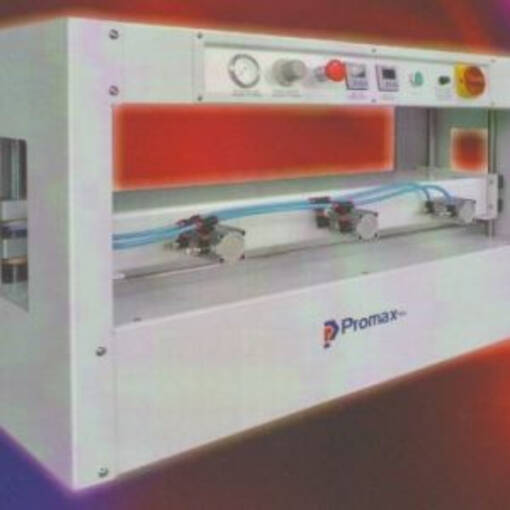

The VT-400 is a heavy-duty, semi-automatic tray sealing system designed for MAP (Modified Atmosphere Packaging) of food trays. Built for small- to medium-volume operations that demand excellent shelf-life performance and reliable sealing of a broad range of tray shapes and films. Whether you’re packaging meats, prepared foods, fresh produce or ready-meals, the VT-400 delivers high-quality visual appeal, top-level protection, and seamless integration into your production line.

Key Features & Benefits

-

Durable stainless steel construction ensures industrial-grade longevity and hygienic operation.

-

Semi-automatic operation for strong throughput without full automation complexity.

-

Automatic film advance and cutting system accelerates cycle time and boosts consistency.

-

PNC-01 microprocessor control panel with 14 programs and IP56 water-resistant rating – offering both versatility and durability in moist food-processing environments.

-

Printed film registration system to maintain perfect alignment and appearance and reduce film waste.

-

Comes standard with a reliable vacuum pump (by BUSCH) and internal gas‐holding tank for consistent MAP performance.

-

Auto tray lift system for easier tray removal post-sealing, reducing operator fatigue and improving ergonomics.

-

Film tensioner built in to ensure optimal film lay and seal quality.

Technical Highlights

-

Maximum tray size: 290 mm × 360 mm (≈11.4″ × 14.2″) up to two trays side-by-side.

-

Maximum tray height: 90 mm (≈3.5″) – accommodates many common food trays.

-

Film roll capacity: up to 400 mm outer diameter, 76 mm inner diameter.

-

Vacuum pump capacity: 40 m³/h (2 hp / 2 kW) standard.

-

Footprint: 1263 × 1165 × 1600 mm (50″ × 46″ × 63″); Weight: 414 kg / 913 lbs.

-

Designed to be adaptable — custom tray & film configurations are supported.

Why the VT-400 Makes a Difference

In competitive food-packaging markets where shelf life, presentation and speed all matter, the VT-400 elevates your packaging game. By combining reliable MAP capability with precision film and tray handling, it helps you achieve longer shelf life, fewer film waste issues, and consistent aesthetic results. For operations upgrading from basic tray sealing or manual processes, the VT-400 provides a smart balance of automation, flexibility and cost-control.

Ideal For

-

Meat processors, poultry or seafood packagers requiring modified-atmosphere sealing for trays.

-

Prepared-meal, deli or fresh-cut-produce operations needing strong shelf-life and clean presentation.

-

Facilities shifting away from manual tray sealing toward a semi‐automated, higher-throughput environment.

-

Producers who want versatility to handle multiple tray formats and film types with one machine.