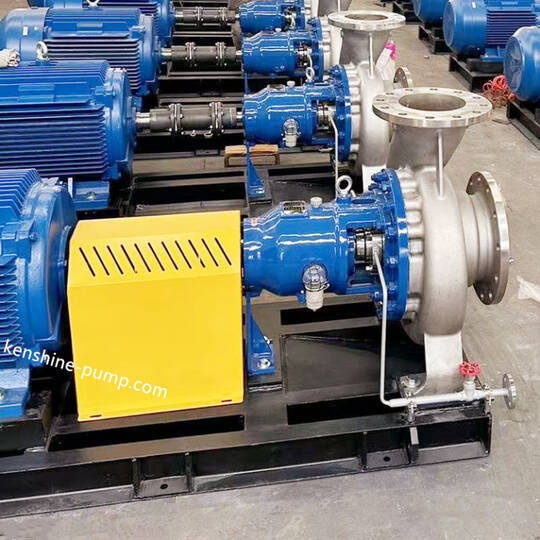

A single-stage, end-suction stainless-steel process pump engineered for chemical and petrochemical applications where reliability, corrosion resistance and ease of maintenance are essential. Designed to handle neutral or corrosive liquids, both low and high temperature fluids, and liquids that are clean or contain entrained solids, this pump suits transfer, circulation, loading/unloading and general process duties.

Key features

- Robust stainless-steel wet end (pump casing and impeller) for corrosion resistance in aggressive environments.

- End-suction, single-stage design for compact footprint and straightforward installation in process piping.

- Axial thrust reduction through an impeller balance hole or balanced impeller design to protect the shaft seal and bearings.

- Multiple sealing options: soft packed (gland) seal (with optional cooling), single- or double-face mechanical seals in a variety of configurations to match process requirements.

- Heavy-duty shaft and bearings sized for long life and smooth operation under continuous duty.

- Dual-volute pump casing available on selected sizes to reduce radial loads and improve reliability.

- Back pull-out design: the bearing frame assembly (shaft, impeller, seal/stuffing box) is removable as a unit so the pump casing can remain in the pipework for fast maintenance; with an extended coupling the motor can also remain in place.

- Flanged connections available to PN16 or PN25 ratings depending on material selection and process pressure.

Benefits for industrial buyers

- Reduced downtime: back pull-out design and standardized sealing options speed routine service and spare parts replacement.

- Flexible sealing and cooling arrangements to adapt to volatile, abrasive or high-temperature services.

- Balanced hydrodynamics and rugged bearings lower vibration and extend service life in continuous process environments.

- Suitable for integration into chemical, petrochemical and general process plant systems where stainless construction and reliable sealing are required.

Typical applications

- Chemical transfer and dosing

- Corrosive liquid handling in petrochemical processes

- Circulation and cooling systems

- Tank-to-tank transfer, loading/unloading

Available options and accessories

- Choice of seal types (packed gland, single or double mechanical seals)

- Casing and impeller surface finishes or specific stainless grades (specify at order)

- PN16 or PN25 flanged connections

- Baseplate, coupling guard and instrumentation (flow, pressure) accessories on request

For specification and selection, provide required flow, head, fluid properties (temperature, viscosity, solids content and chemical compatibility) so a suitable model and seal arrangement can be recommended.

Product Details

Harmonized commodity

Brand:

kenshine-pump

Country of origin:

China

Industrial sector:

SKU:

SET

GTIN/EAN:

841370

MPN:

CZ

Model:

CZ65-250

Unit type:

Set

Minimum order (MOQ):

1