Horizontal, fluoroplastic-lined magnetic-drive centrifugal pump designed for leak-free transfer of aggressive, toxic or high-purity liquids. All wet parts are manufactured from fluoropolymers (PFA / FEP / F46) to provide outstanding chemical resistance against strong acids, strong alkalis, halogenated and non‑halogenated organic solvents, and other corrosive or precious process fluids.

Key features

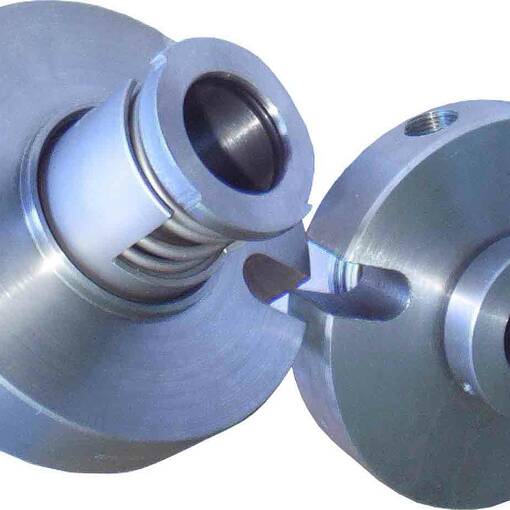

- Magnetic drive (hermetically sealed): indirect magnetic coupling eliminates the shaft seal and the risk of external leakage or emissions, ensuring safe, zero‑leakage operation for hazardous or valuable media.

- Fluoroplastic wet end: PFA/FEP/F46 lining throughout the pump chamber and wetted components for maximum corrosion resistance and process purity.

- High-performance rotor assembly: NdFeB (neodymium) magnets encapsulated and protected by PFA; rotor shaft in silicon carbide for excellent chemical resistance, wear resistance and high-temperature performance.

- Shaft material: dense, sintered silicon carbide provides high mechanical strength, abrasion resistance and compatibility with organic solutions at any concentration.

Performance range

- Flow: 0.6 to 100 m3/h

- Head: 2 to 50 m

- Motor power: 0.18 kW to 30 kW

Applications

- Chemical processing (acids, alkalis, solvents)

- Pharmaceutical and fine chemicals where product purity and low contamination are critical

- Electroplating, pickling and surface treatment baths

- Petrochemical and refinery feed/transfer of aggressive streams

- Laboratories and process plants handling toxic, flammable or high‑value liquids

Benefits for B2B purchasers

- Zero-leak design reduces compliance risk, environmental impact and secondary containment requirements

- Long service life in corrosive environments thanks to fluoropolymer linings and silicon carbide internals

- Low maintenance: magnetic coupling reduces wear-prone dynamic seals and associated downtime

- Flexible sizing and motor options to match process flow and head requirements

Options & notes

- Available in multiple sizes and power ratings to suit different process demands

- Select lining (PFA/FEP/F46) and motor specification to match chemical compatibility and temperature requirements

- Ensure correct installation (base mounting, alignment, and appropriate motor/inverter selection) and follow manufacturer guidelines for start-up and routine inspection of magnet coupling and bearings.

For specification confirmation (materials, temperatures, viscosities, particulates, and exact model selection), provide process fluid data and operating conditions to ensure material and hydraulic compatibility.

Product Details

Harmonized commodity

Brand:

kenshine-pump

Country of origin:

China

Industrial sector:

SKU:

600SETS

GTIN/EAN:

841370

MPN:

CQB65-50-160F

Model:

CQB50-32-160F

Unit type:

Set

Minimum order (MOQ):

1