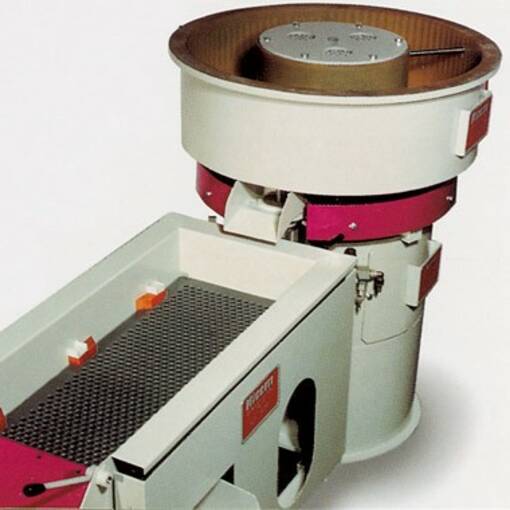

Wet blasting cabinet designed for cleaning, degreasing, and finishing metal surfaces in industrial environments. Manufactured nationally and constructed according to applicable regulations, it can be supplied in stainless steel or carbon steel depending on strength and corrosion requirements. We offer custom manufacturing and solutions for integration into fully automated processes.

Main Features:

- Standard models available: VAQ 1000 x 1000, VAQ 1250 x 1250, and VAQ 1500 x 1500.

- Internal rotating tray included in all models, facilitating uniform treatment of parts.

- Option to incorporate an auxiliary loading table to facilitate handling and productivity.

- Customization options for abrasive recovery and separation, effluent management, and process accessories (according to customer specifications).

Advantages of wet blasting:

- Fast, versatile, and economical system for surface cleaning and finishing.

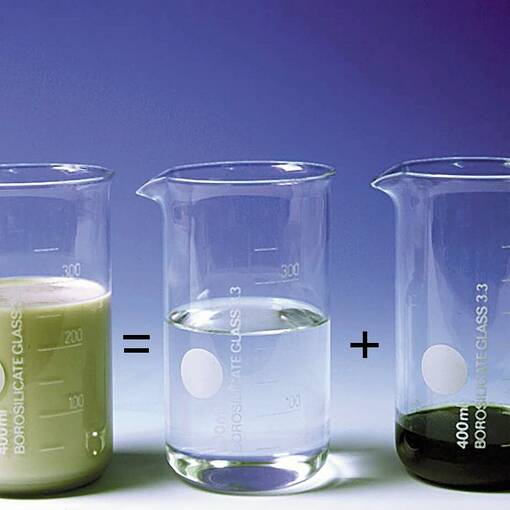

- Reduces or eliminates the need for aggressive, acidic, or degreasing chemicals and subsequent manual cleaning.

- Enables degreasing, deoxidizing, and burr removal without damaging edges or delicate surfaces.

- Improves surface preparation for subsequent processes (painting, recovery, heat treatments) and produces controlled satin or matte finishes.

Typical applications:

- Cleaning and deburring of metal parts

- Removal of oxides and contaminants

- Surface preparation for painting or coatings

- Cleaning of molds and tooling

- Pre-plating, anti-glare, and satin finishes

- Light blasting and impact blasting with abrasives

We supply equipment tailored to industrial needs, with the option to integrate specific features and automation to increase productivity and ensure process repeatability. For custom projects and technical advice, we can prepare proposals based on part dimensions, production rates, and finish requirements.