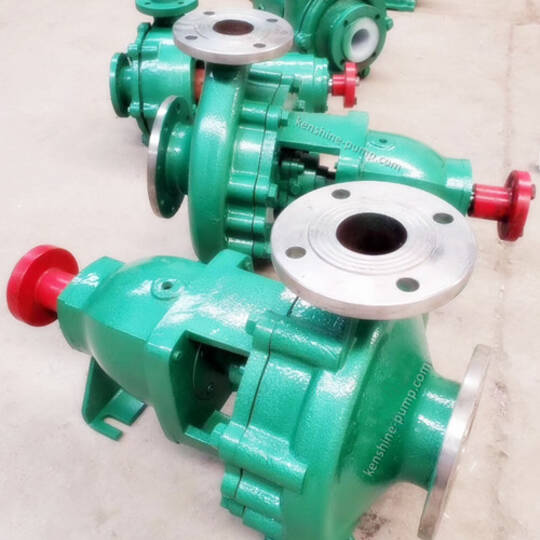

A robust surface-mounted centrifugal pump engineered for reliable transfer of clean and moderately contaminated liquids from open sources such as wells, rivers, reservoirs and storage tanks. Designed for easy installation and servicing, this pump is ideal for household, agricultural and industrial water supply, irrigation, dewatering and general liquid-handling duties.

Key features

- Simple ground-mounted installation — no submergence required, easier access for inspection and maintenance.

- Proven centrifugal hydraulics with options for self-priming where required.

- Modular construction: motor, pump casing, impeller, mechanical seal, coupling and support bracket for straightforward replacement of wear parts.

- Multiple mechanical seal and coupling options to suit water and chemical applications.

- Configurable orientation: available in vertical or horizontal arrangements and in close-coupled or shaft-coupled layouts.

- Material options to match fluid compatibility and duty: cast iron, stainless steel, duplex stainless steel; plastics such as polypropylene (PP), fluoroplastics (F46/FEP/PTFE) and PVDF.

Typical applications

- Municipal and domestic water supply

- Agricultural irrigation and sprinkler systems

- Industrial process water transfer and recirculation

- Site dewatering and drainage

- Transfer of corrosive or chemically aggressive liquids (select plastic or corrosion-resistant metal variants)

Benefits for procurement teams

- Reduced installation time compared with submersible alternatives — pump remains accessible for inspection and servicing.

- Flexible configurations and materials let you match pump selection to flow, head and fluid compatibility requirements.

- Standardized spare parts (impellers, seals, couplings) simplify stocking and reduce downtime.

Operation and maintenance guidance

- Choose a stable, level mounting close to the source and ensure proper alignment of suction/discharge piping.

- Verify motor and electrical connections meet local codes and nameplate requirements before start‑up.

- Regular inspections: check for vibration, seal leaks, impeller wear and bearing condition.

- Keep inlet strainers and suction lines clear of debris to avoid cavitation and impeller damage.

- Replace mechanical seals and worn impellers promptly to maintain efficiency and prevent failures.

- For long-term storage, drain, clean and store in a dry, dust‑free environment.

Ordering options

Available in multiple sizes and performance ranges with configurable materials, shaft coupling types and sealing arrangements. Specify required flow (m3/h or GPM), total head (m), liquid characteristics, preferred materials and mounting style when requesting a quotation to ensure correct model selection.