Horizontal stainless-steel pipeline centrifugal pump engineered for reliable transfer of corrosive, low-viscosity liquids without solids. Constructed in stainless steel (SUS304, SUS316, SUS316L) and fitted with a hard-alloy mechanical seal, this single-stage, single-suction pump is suitable for continuous service in demanding chemical and industrial environments.

Key features

- Stainless-steel wetted parts for corrosion resistance and hygienic service

- Hard-alloy mechanical seal to minimize leakage and extend service life

- Horizontal inline (pipeline) design for compact installation and easy piping

- Compatible with standard or explosion-proof motors for hazardous areas

- Stable hydraulic performance with low vibration and noise

- Modular arrangement allows pumps to be run in series or parallel to meet specific duty requirements

- Designed for easy access and routine maintenance

Typical applications

Suitable for handling corrosive liquids with viscosities close to water and no entrained solids. Common sectors include petroleum and chemical processing, metallurgy, power generation, pulp & paper, food and pharmaceutical production, and synthetic fiber manufacture.

Performance and material options

- Flow rate (Q): 2 to 1,500 m3/h

- Head (H): 3 to 125 m

- Inlet/outlet diameter range: 15 to 600 mm (example model shown below)

- Liquid temperature range: -20 °C to 120 °C

- Standard materials: SUS304, SUS316, SUS316L

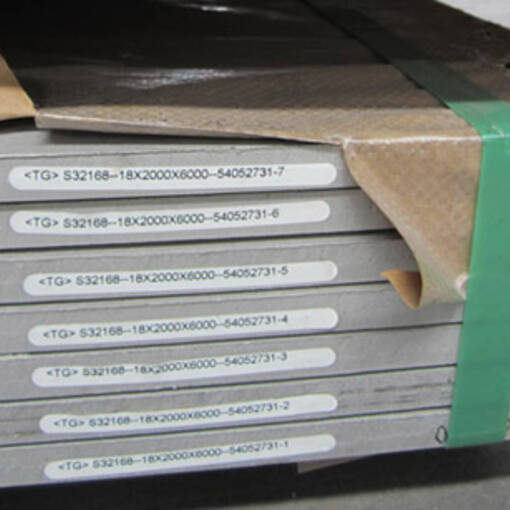

Model example

- ISWH50-160: ISWH = stainless-steel chemical centrifugal pump; 50 = inlet/outlet diameter (50 mm); 160 = nominal impeller diameter (160 mm)

Ordering & customization

Available with different stainless-steel grades, mechanical seal types, motor ratings (including explosion-proof), and flange/end-connection options to match site requirements. Provide required flow, head, liquid properties, temperature, and preferred materials when requesting a quote to ensure correct selection.

Notes

For corrosive or critical services, confirm material selection (SUS grade) and seal type against the specific chemical compatibility and operating temperature. Pumps may be installed in series or parallel to achieve higher head or flow as required.