A heavy-duty submerged pump engineered for heated, insulated transfer of molten sulfur and other high-temperature, high-viscosity liquids. The unit uses submerged gear-pump technology with an insulated jacketed pipeline to maintain product temperature in the suction and discharge lines. Precise machining and component matching plus variable-frequency drive (VFD) control deliver stable, low-pulsation flow with low motor power and long service life.

Key features

- Designed specifically for insulated, heated media: molten sulfur, liquid asphalt, liquid paraffin, high-temperature coal tar, etc.

- Submerged (in-tank) installation — pumps liquid directly from storage tanks into process piping, minimizing leak risk and exposure to toxic or polluting fluids.

- Japanese submerged gear pump design: positive-displacement performance for consistent flow across a wide viscosity range.

- VFD (variable-frequency) flow control enables accurate flow metering and soft-start operation to reduce mechanical stress and energy use.

- Insulation jacket option for discharge piping and export lines to retain temperature during transfer.

- Bi-directional capability (forward/reverse) so the pump can flush blocked inlets by reversing rotation.

- Adjustable internal gap to restore performance after wear without full disassembly.

- Low pulsation and continuous conveyance avoid vortexing and no-load running.

Typical specifications

- Flow rate: 0.1 – 60 m3/h

- Pressure: up to 16 bar

- Viscosity range: 0.1 – 10,000 cP

- Temperature range: -30 to 410 °C

- Maximum submerged depth: ≤ 2 m

Materials and construction

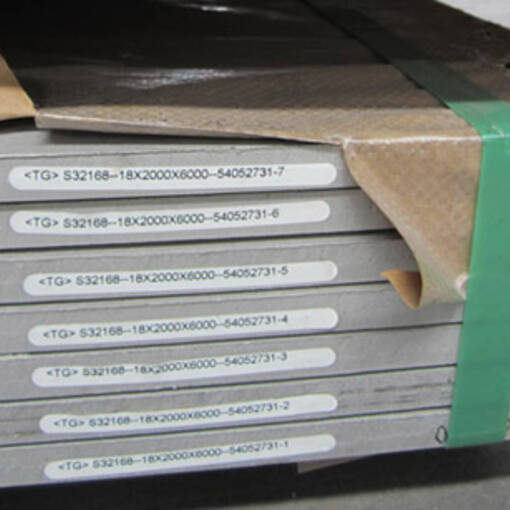

- Pump body options: cast iron, ductile iron, 304 stainless steel, 316 stainless steel — selectable to match media compatibility and corrosion resistance requirements.

- Precision manufacturing and tight tolerances for long service intervals and reliable performance in demanding thermal service.

Applications and benefits

- Commonly used in petroleum, chemical, asphalt, sulfur processing, viscose and other industries handling hot, viscous, or hazardous liquids.

- Eliminates the need for separate priming systems and reduces the risk of leaks and worker exposure by pumping directly from tanks.

- Insulated piping and temperature control preserve product viscosity and flowability, reducing blockages and downtime.

Options and customization

- Frequency converter/VFD for flow control and soft start

- Choice of construction materials and seals to suit chemical compatibility and operating temperature

- Insulated export/discharge piping

- Configurable inlet/outlet sizes and mounting for tank integration

Provide operating parameters and fluid specifications when ordering (temperature, viscosity, specific gravity, solids content) so the pump can be supplied and configured to meet your process requirements.