-

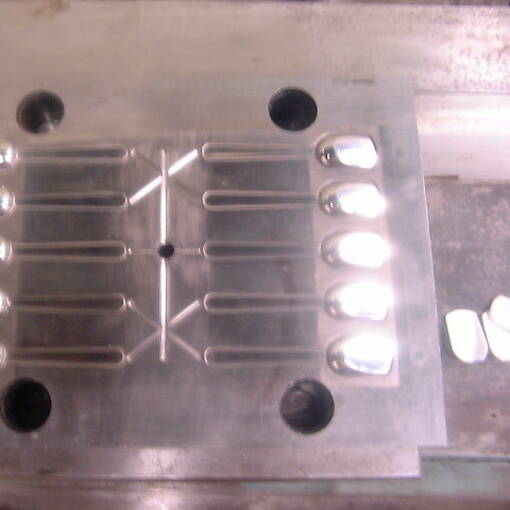

Rubber molds designed for the production of perforated gypsum (plaster) boards intended for fixed or suspended acoustic ceilings. They are intended for the repetitive reproduction of pieces with uniform perforations and textures, optimizing production processes in both industrial and specialized workshop environments.

-

Main Features and Benefits:

- Flexibility and elasticity of the rubber facilitate demolding without damaging the gypsum board.

- Allow precise reproduction of perforations, reliefs, and surface finishes, reducing rework.

- Improve productivity by enabling rapid and repeatable molding cycles.

- Compatible with gypsum/plaster and other cement-based compounds used in acoustic panels.

- Customizable design: perforations, dimensions, and number of cavities can be adjusted according to project requirements.

-

Usage Recommendations:

- Apply an appropriate demolding agent to prolong the mold's lifespan and facilitate demolding.

- Clean and dry the mold after each cycle to prevent dust and plaster residue accumulation.

- Verify curing and setting time of the cast material according to the formulation used; times vary depending on the mixture and environmental conditions.

-

Typical Applications:

- Manufacturing of perforated acoustic panels for fixed or suspended ceilings in offices, auditoriums, commercial spaces, and industrial facilities.

- Series production in prefabrication plants and interior finishing workshops.

-

Supply Options:

- Single molds or sets based on the required number of cavities.

- Custom design according to the client's technical specifications (perforation pattern, dimensions, and number of cavities).

Ideal for construction companies, acoustic panel manufacturers, and prefabrication workshops seeking to standardize and streamline the production of perforated gypsum ceilings.

Product Details

Harmonized commodity

Country of origin:

Spain

Industrial sector: